INDUSTRY NEWS

What should be considered when using cnc lathe metal?

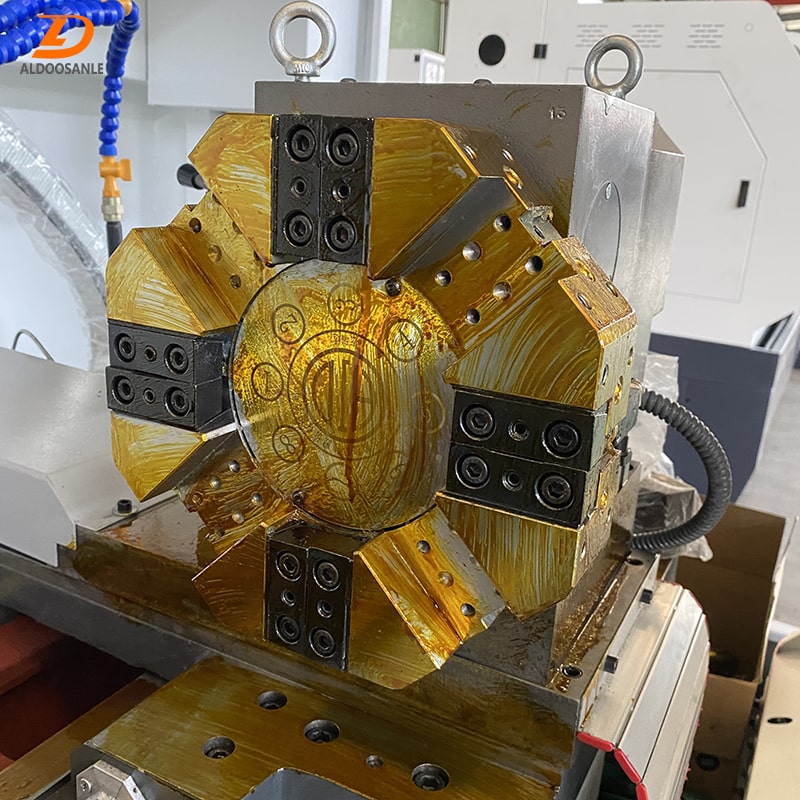

High precision cnc lathe has the characteristics of mechanical and electrical integration. Flat bed cnc lathe machine is an advanced processing equipment with high degree of automation and complex structure.

CNC lathe machine can process the inner and outer cylindrical surfaces of shaft parts or disc parts, etc.

When machining with CNC Mini Lathe, the following aspects should be considered:

1. The shape and position accuracy requirements of CNC Lathe Metal:

The shape and position tolerance given on the part pattern is an important basis for ensuring the accuracy of the part.

During processing, it is necessary to determine the position and measurement standards according to its requirements, and to process certain technologies according to the special needs of Automatic CNC Lathe to effectively control the accuracy of shape and position.

2.Material and heat treatment requirements:

The material and heat treatment requirements given on the part drawing are the basis for selecting the tool and CNC Horizontal Lathe type and determining the stock removal.

Surface roughness requirements for CNC Lathe Flat Bed:

Surface roughness is an important requirement to ensure the microscopic accuracy of the surface of the part, and it is also the basis for the reasonable selection of cnc horizontal lathe machine, cutting tool and cutting parameters.

Dimensional accuracy requirements for machining high precision cnc lathe:

Analyze the dimensional accuracy requirements of part drawings, determine whether the enterprise can effectively use the turning process to achieve, and determine the process research method for risk control of dimensional accuracy.

During the analysis and development of this work, some basic dimension transformations such as incremental dimensions and dimensions and dimension chain calculations can also be learned.