INDUSTRY NEWS

Using cnc lathe instead of grinding to bring new technology changes in the mold industry

Die Industry Carbide materials are often used in stamping, drawing and extrusion dies. Due to the extremely strong wear resistance of cemented carbide materials, and the complex contours of these molds, which need to meet extremely high contour accuracy and surface finish, the traditional grinding process is completed by special diamond grinding wheels.

However, manufacturers continue to face the challenges of reducing costs, improving quality and increasing efficiency.

It turns out that high-precision hard turning (replacing grinding with a cnc lathe machine) helps achieve these goals.

What is a high precision cnc lathe to replace the grinder?

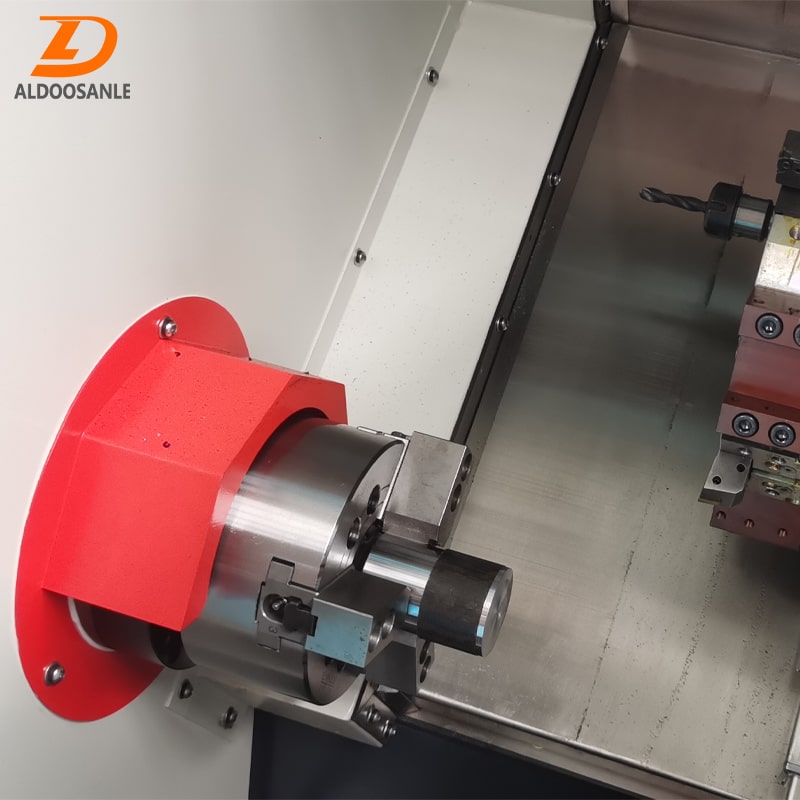

High Precision horizontal cnc lathe machine turning is a very flexible process. The Mini metal lathe machine is simple to set up/easy to change. The metal lathe mini can complete the turning of the inner hole and the outer circle in one clamping. The metal lathe machine is beneficial to reduce the cumulative error and improve the part accuracy.

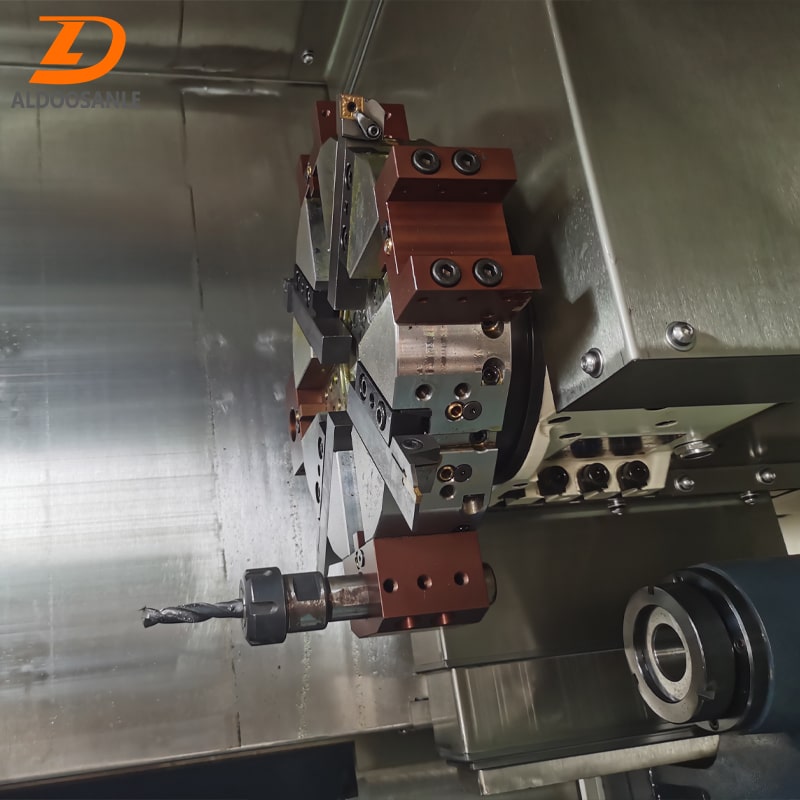

At the same time, CNC mini lathe turning has a higher metal removal rate, which means that CNC lathe metal can improve efficiency. However, the biggest advantage of CNC Lathe is that it can easily process complex part contours. Different part contour shapes can be accurately generated by the ultra-precision Automatic CNC Lathe through the CNC program, using the method of multi-axis interpolation.

In the case of grinding, however, multiple setups are often required to complete complex shaped workpieces, and the wheel needs to be replaced for each contour that requires a specific wheel shape to be machined. So for small batch processing, this can significantly affect the processing efficiency.

The flexible manufacturing process of carbide parts (turning instead of grinding) is now possible with CNC Lathe Turning with excellent dynamic rigidity and ultra-high precision, as well as new diamond inserts.

In order to realize this flexible manufacturing process, an ultra-high precision CNC Horizontal Lathe is necessary.