INDUSTRY NEWS

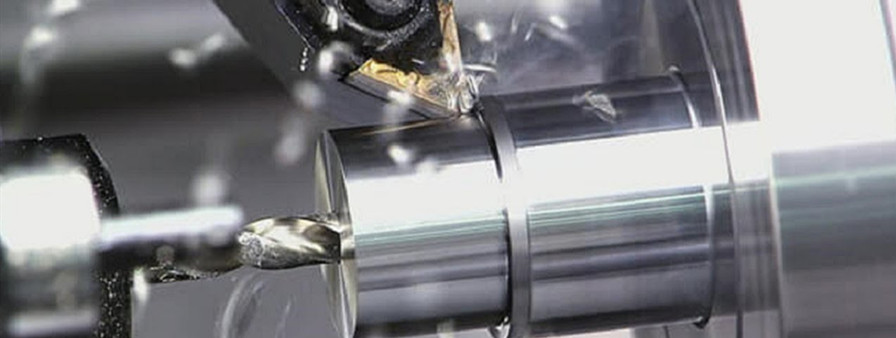

How to improve the quality of CNC turning parts?

1. Before Aldoosanlecnc high precision cnc lathe processing, please use a calibrator to check whether the CNC inserts are shaken within the allowable dimensional tolerance range. Before machining with the flat bed cnc lathe machine, use a heat gun to clean the blade and lock the nozzle, or wipe the installation tool with a cloth.

2. The flow chart specification of CNC turning files should be standardized, including model specification, name, program process name, processing content, CNC blade specification, cutting speed, especially the reliable length of Aldoosanlecnc CNC lathe manufacture tool holder, the embedding ability of each program process and Its display lights and knives must be raised significantly.

3. The specification of the Aldoosanlecnc cnc lathe machine processing flow chart should be consistent with the reference angle marked on the mold, and then check the 3D picture above, especially the product workpiece that has been drilled through water, be sure to check whether the 3D picture is correct and the product workpiece the same level.

4. Before Aldoosanlecnc cnc lathe processing, you must master the content of the Aldoosanlecnc mini cnc lathe machine processing program flow. The program flow must have 2D or 3D3d textures, and must be marked with "X length, Y width, Z height" hexagonal data information. "Z" value. It is convenient for the operator to check whether the program is suitable after the processing of the Aldoosanlecnc mini cnc lathe. If there is a dimensional tolerance, the dimensional tolerance data information should be indicated.

5. Reasonable use of special tools for CNC turning. Strictly distinguish the processing of stainless steel plate and copper public light knife. The allowance of the smooth knife should be effective to make the finish of the product and the service life of the CNC blade possible and stronger.

6. When clamping, pay attention to whether the workpiece name, model specifications and flow chart specifications processed by Aldoosanlecnc cnc mini metal lathe are consistent, whether the specifications of the raw materials match, whether the relative height of the clamping is high enough, and the total number of calipers used.

7. The speed of CNC turning should be strictly controlled by the operator. The F-rate of the Aldoosanlecnc lathe machine mini cnc and the spindle speed of the S machine should be adjusted effectively. When the F speed is fast, the S machine tool spindle should be accelerated. The feed rate has to be adjusted in different areas. After processing, check the quality and there is no problem, you can get off the car and process it well.