PRODUCT

CNC Lathe Flat Bed ALCK6150 can reduce labor

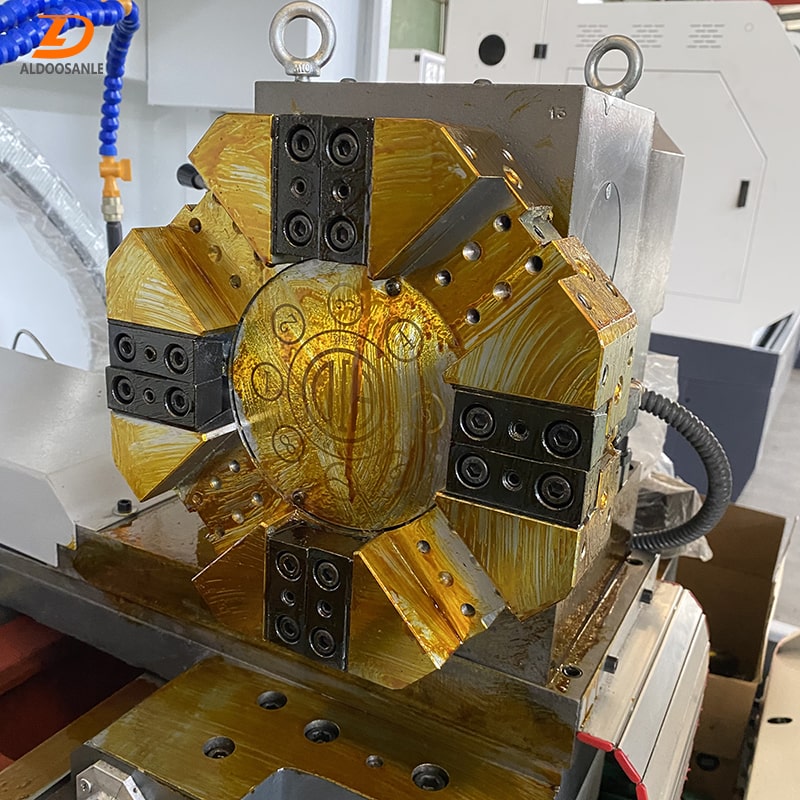

Flat bed cnc lathe machine can process straight thread, tapered thread, face thread etc.

When machining hardware in cnc lathe manufacture, all rotating parts that can be clamped with ordinary lathes can be machined with cnc lathe.

Mini cnc lathe machine has high machining precision in the process of hardware processing, and has the characteristics of linear arc interpolation and automatic speed change, and its technical scope is much wider than that of ordinary machine tools.

CNC lathe machine is a machining method that uses digital information to control the displacement of parts and tools. It is a high-precision and high-efficiency automated machine tool that can solve the problems of changing aerospace product parts, small batches, complex shapes, and high precision. An effective way to automate processing.

Product Features

1. The degree of automation is high, which can reduce the manual labor intensity of operators. The machining process of the mini lathe milling machine is automatically completed according to the input program. The operator only needs to start tool setting, loading and unloading workpieces, and changing tools, and then he can observe and supervise the operation of the lathe.

2. The machining parts have high precision and stable quality. The Heavy Duty CNC Lathe Machine has high positioning accuracy and repeatable positioning accuracy, and it is easy to ensure the consistency of the size of a batch of parts. As long as the process design and procedures are correct and reasonable, and the operation is careful, the parts can obtain higher machining accuracy and facilitate the quality control of the machining process.

3, cnc lathe metal and its processing technology are the basis of computer-aided manufacturing, which can be developed to more advanced manufacturing systems.

4. Large initial investment. CNC lathe machining equipment costs are high, the initial processing preparation cycle is long, and the maintenance cost is high.

5. High maintenance requirements. CNC Mini Lathe is a typical product of mechatronics and is technology-intensive. Maintenance personnel understand mechanical, microelectronic maintenance, and are equipped with better maintenance equipment.

6. CNC Lathe Metal processing provides shortcuts for new product development, product improvement and improvement; it can greatly shorten the product development cycle,

7. The quality of the parts processed by CNC Lathe Machine Horizontal is stable, which is convenient for subsequent processes, and the overall efficiency is significantly improved.

The main workpieces processed by cnc lathe machine:

The mini cnc lathe has high rigidity, high precision in manufacturing and tool setting, and can easily and accurately enter manual correction and automatic correction, so it can process parts that require dimensional accuracy.

The tool movement of CNC mini metal lathe is realized by high precision interpolation movement and servo drive. The lathe machine mini cnc can process parts with high rigidity, high manufacturing accuracy, and the shape accuracy of busbar straightness, roundness and cylindricity. For arcs and other curved profiles, the machined shape is closer to the geometry required by the drawing.

The cnc mini metal lathe machine has the function of fixed line speed cutting, which can cut the tapered surface and end face with a better line speed, which can make the surface roughness value after turning small and uniform, and can process the surface roughness value small and uniform. Components.

CNC lathe turning can not only process lead straight thread, tapered thread, face thread, but also process lead thread and smooth transition between them.

When CNC horizontal lathe is turning threads, the rotation of the spindle does not need to be changed alternately like ordinary lathes, and it can be continuously cycled before it is completed, so threading on automatic cnc lathe is very efficient.

Video

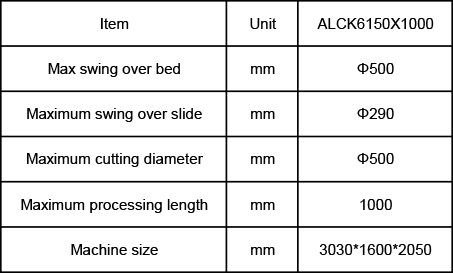

Product Parameters