PRODUCT

ALCK6160X2000 cnc lathe machine

ALCK6160×2000 cnc lathe machine CNC lathe is made of cast iron, rolled bamboo bar and sheet, it is a new type of CNC lathe. ALCK6160×2000 series CNC horizontal lathe has the characteristics of high precision, high power, high rigidity, etc. Its main components and structure have been optimized.

ALCK6160×2000 cnc lathe machine is a CNC lathe with high precision, high performance and strong versatility. It is used to process various shaft and disk parts. It can automatically complete the processing of internal and external circular surfaces, conical surfaces, arc surfaces, end surfaces and other rotary surfaces, as well as turning threads. It is suitable for high-volume and high-efficiency processing of various high-precision, complex, medium and small rotary parts in the industries of instrumentation, electronic engineering, medical equipment, aerospace, auto parts, and textiles.

ALCK6160×2000 turning cnc lathe features:

1. High precision, high rigidity, wide application, complete functions, etc.

2. At the same time, it has good precision stability and retention

3. The bus-type numerical control system, two axes (vertical axis Z axis, horizontal X axis) linkage, can automatically complete the turning of various metric and inch threads of the outer circle, inner hole, arc surface, cone surface, end surface, and special-shaped surface of the part.

4. Good stability and long life;

5. Easy to use and maintain.

ALCK6160×2000 turning cnc lathe use:

1. Parts processing: ALCK6160×2000 horizontal cnc lathe is widely used in parts processing fields of automobile, aerospace, electronics and other industries. It can efficiently and precisely process various parts with complex shapes, such as gears, threads, apertures, etc., to meet the requirements of industrial manufacturing

2. Mold processing: Mold making is a part of modern manufacturing industry. ALCK6160×2000 horizontal cnc lathe has advantages in the field of mold processing. It can realize multi-angle and multi-axial processing and improve the precision and efficiency of mold making

3. Steel processing field: ALCK6160×2000 horizontal cnc lathe can be used to process bearings, bushings, journals and other parts to improve production efficiency and product quality. Its excellent performance and reliability make it a key tool in the processing field and promote the development and progress of related industries.

4. In the field of power generation equipment: ALCK6160×2000 automatic cnc lathe is widely used in the processing of key components of wind turbines, such as horizontal spindles, wind wheels, gearboxes, generators, etc., which are difficult to process and require high precision. CNC machine tools can better solve complex, precise, small-batch, and multi-variety parts processing problems.

ALCK6160×2000 automatic cnc lathe standard configuration:

1. Ordinary main motor

2. Domestic frequency converter

3. Three-jaw chuck

4. Tailstock

5. Four-station electric knife holder

6. Automatic lubrication system

7. Electric cooling system

8. Lighting system

9. Semi-enclosed shield

10. Electrical control components

11. A full set of technical information

12. Random standard accessories and tools

ALCK6160×2000 automatic cnc lathe optional configuration:

1.Integral bed foot

2.Eight-station electric knife holder

3.Hydraulic Chuck

4.Electric chuck

5.Hydraulic tailstock

6.Center bracket

7.Frequency conversion motor

8.Servo motor

9.Electric gate

video:

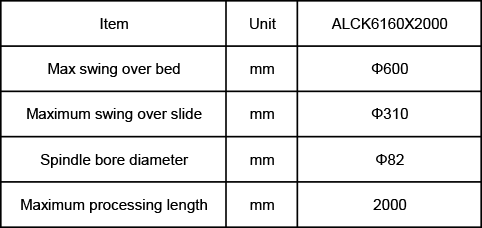

Product parameters: