PRODUCT

ALCK6180×2000 cnc lathe machine

ALCK6180×2000 cnc lathe machine is an economical and practical CNC lathe with mature structure, stable performance, high quality, easy programming and simple operation. It is suitable for the inner and outer surfaces, conical surfaces, arc surfaces, Drilling, reaming and reaming of various threads and even holes are especially suitable for the sequential processing of multiple varieties and small and medium batches of parts.

ALCK6180×2000 cnc lathe machine is suitable for processing all kinds of steel, cast iron and non-ferrous metal large and medium-sized parts.ALCK6180×2000 CNC machine tool has high power and good rigidity. It is especially suitable for powerful cutting, cutting inner circle, outer circle, end face, and metric and inch parts of various workpieces. Thread, etc., and can undertake drilling and boring processes.

ALCK6180X2000 flat bed CNC lathe features:

1. High stability hard rail bed

2. The main shaft has three gears, stepless frequency conversion speed regulation within the gear

3. High-strength base

4. Widened carriage

5. Automatic centralized lubrication

ALCK6180×2000 Horizontal CNC Lathe Application:

1. Railway locomotive manufacturing industry: ALCK6180×2000 automatic numerical control lathe is aimed at high-speed rail locomotive body, axle, wheel and other parts.

2. Mold processing and manufacturing industry: the precision of parts is required to be high, and the surface precision mainly refers to the surface roughness. Cylindrical parts that require high cylindricity; conical parts that require high plane straightness, roundness, and inclination; rotating parts with special threads. ALCK6180×2000 automatic numerical control lathe can solve this problem well.

3. Defense industry: The ability of ALCK6180×2000 automatic CNC lathe to provide replacement parts and upgrade components on demand is especially useful in this industry. Therefore, it is suitable for components that require continuous innovation and safety.

4. Medical business field: ALCK6180×2000 flat bed CNC lathe can be used for various medical safety materials. Since the process is suitable for one-off custom parts, it has many applications in the medical industry. The tight tolerances offered by the ALCK6180×2000 flatbed CNC lathe machining are critical for high-performance machining of medical components.

ALCK6180×2000 turning cnc lathe standard configuration:

1.CNC system,

2.Integral landing bed,

3.Heavy-duty rail width 600mm,

4.11KW ordinary main motor,

5.11KW domestic frequency converter,

6.CK6180 (Φ630 manual four-jaw chuck or Φ400 three-jaw chuck),

7.manual tailstock,

8.Four-station electric tool post,

9.automatic lubrication system,

10.electric cooling system,

11.Lighting system,

12.semi-enclosed shield,

13.Delixi electrical control components,

14.A full set of technical information,

15.Random standard accessories and tools.

ALCK6180×2000 turning cnc lathe optional configuration:

1.Square head gear box three-speed variable frequency segmental variable speed CNC lathe

2.Optional manual four-speed internal stepless transmission,

3.Optional spindle servo motor (11KW).

video:

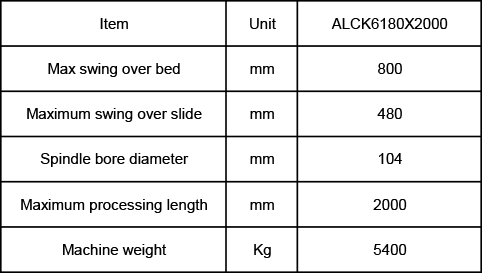

Product parameters: