PRODUCT

Large CNC lathe ALCK61125X1500: a sharp tool for precision machining

This article introduces the characteristics, application industry, standard configuration and optional configuration of large CNC lathe ALCK61125X1500. This CNC lathe has high-precision and high-efficiency processing capabilities and is widely used in aerospace, automobile manufacturing, energy equipment and other fields. The standard configuration and optional configuration can meet the processing needs of different users and improve production efficiency and product quality.

With the continuous development of the manufacturing industry, large-scale CNC equipment plays a vital role in various fields. Among them, the large CNC lathe ALCK61125X1500 has become the target pursued by many manufacturing companies because of its excellent performance and multi-functional features. This article will deeply discuss the characteristics, application industry, standard configuration and optional configuration of ALCK61125X1500 CNC lathe, and give you a comprehensive understanding of this powerful tool in the field of modern manufacturing.

Features of CNC lathe ALCK61125X1500:

1. High-precision processing: ALCK61125X1500 CNC lathe adopts advanced CNC technology, which can achieve micron-level processing accuracy, and is suitable for the processing requirements of high-precision parts.

2. High-efficiency production: The equipment is equipped with a powerful spindle and feed system, which can realize high-speed and high-efficiency processing operations and improve production efficiency.

3. Multifunctional processing: CNC lathes have multiple processing functions, including turning, milling, drilling, etc., and are suitable for integrated processing of complex workpieces.

4. Stability and durability: The equipment has a solid structure and is made of high-quality materials. It has good stability and long-term durability, ensuring long-term stable operation.

ALCK61125X1500 CNC lathe is widely used in the following fields:

1. Aerospace: It is used to manufacture aero-engine parts, aircraft structural parts, etc., to meet the demand for high-precision and high-strength parts in the aerospace field.

2. Automobile manufacturing: It is used in the processing of automobile engine, transmission, chassis and other parts to improve automobile manufacturing process and product quality.

3. Energy equipment: It is used to manufacture key components of wind power, thermal power, nuclear power and other energy equipment to ensure the stable development of the energy industry.

STANDARD CONFIGURATION

(1)GSK980TB3 CNC controller

(2)630mm 3 Jaw manual chuck

(3)4 station electric tool post

(4)auto lubrication system

(5)led lamp

(6)manual tail stock

OPTIONAL CONFIGURATION

(1)Fanuc,siemens,syntec,knd,Mitsubishi

(2)Hydraulic chuck

(3)6/8 station turret

(4)hydraulic tail stock

(5)chip converyor

(6)steady rest

(7)follow rest

(8)living turret with y axis

(9)custom color available

Video

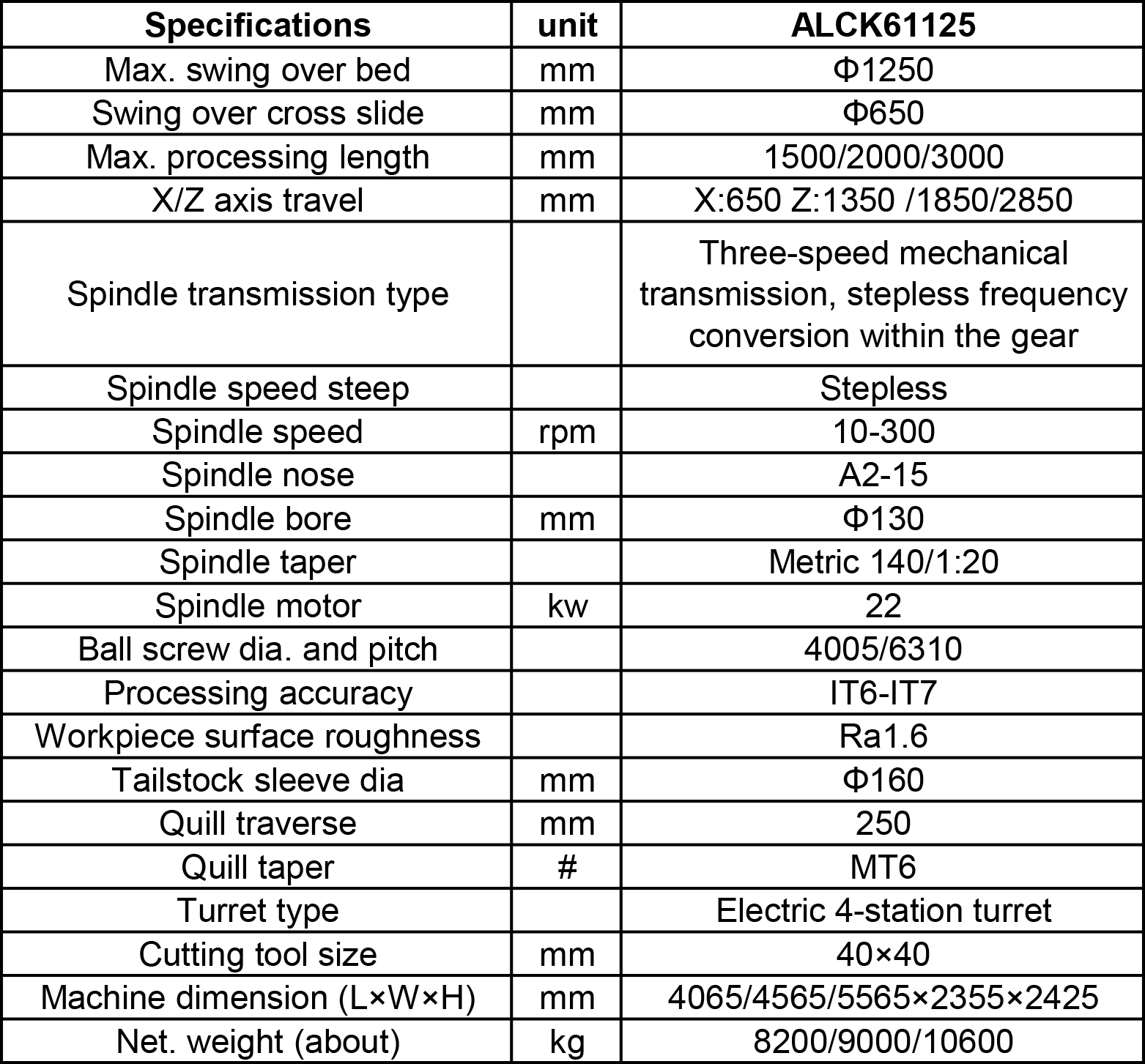

Technical Parameters