PRODUCT

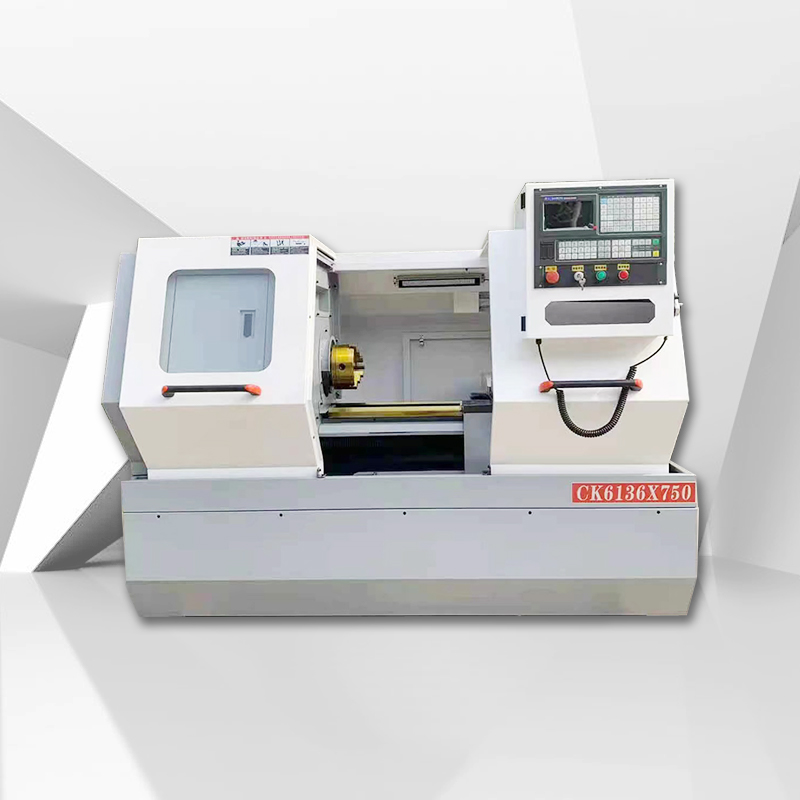

ALCK6136X750 Industrial-Grade Flat Bed CNC Lathe

Brand - ALLES CNC

Model - ALCK6136-750

Core Capacity - ⌀360mm × 750mm

Special Offer - $10,999 → $7,999 (Limited Time)

Availability - In Stock | 15-30 Days Lead Time

Warranty - 12-Month Full Machine

Certification - CE Certified | Factory Direct

Perfect for: Long shafts, lead screws, cylinders.

The ALCK6136X750 cnc lathe is engineered for stable, precision turning of long shaft components. Its rigid flat-bed construction combined with a substantial 750mm Z-axis travel effortlessly handles batch production of motor shafts, lead screws, hydraulic cylinders, and similar workpieces. The machine delivers exceptional core precision, with repeat positioning accuracy of ±0.01mm, consistently achieving IT6-IT7 grade dimensional tolerances and Ra 1.6μm surface finishes. The 5.5 kW frequency conversion spindle provides ample power for efficient cutting operations.

Technical Specifications & Capabilities

Machining Capacity

|

Specification |

Parameter |

|---|---|

|

Maximum Swing Over Bed |

⌀360 mm |

|

Maximum Turning Diameter on Tool Post |

⌀200 mm |

|

Maximum Workpiece Length (Between Centers) |

750 mm |

|

Spindle Through-Hole Diameter |

⌀52 mm |

Spindle System

|

Specification |

Parameter |

|---|---|

|

Spindle Speed Range (Infinitely Variable) |

150 - 2000 rpm |

|

Spindle Motor Power |

5.5 kW (Frequency Conversion) |

|

Spindle Nose Type |

ISO A2-6 |

|

Spindle Nose Taper |

No. 5 Morse Taper |

Motion & Precision

| Specification | Parameter |

|---|---|

| X-Axis Travel | 200 mm |

| Z-Axis Travel | 750 mm |

| Rapid Traverse Speed (X/Z) | 6000 / 8000 mm/min |

| Feed Rate Range | 1 - 2000 mm/min |

| Least Input Increment | 0.01 mm |

| Repeat Positioning Accuracy (X/Z) | ±0.01 mm |

| Workpiece Accuracy | IT6 - IT7 Grade |

| Workpiece Surface Roughness | Ra 1.6 μm |

Tooling System

| Specification | Parameter |

|---|---|

| CNC Tool Post Type | Vertical 4-Station Power Turret |

| Tool Holder Size | 20×20 mm |

| Tool Post Repeatability | ±3.2″ |

Tailstock & Cooling

| Specification | Parameter |

|---|---|

| Tailstock Sleeve Diameter | ⌀60 mm |

| Tailstock Sleeve Travel | 100 mm |

| Tailstock Sleeve Taper | Morse No. 4 |

| Coolant Motor Power | 125 W |

| Coolant Pump Flow Rate | 25 L/min |

Machine Construction & Power

| Specification | Parameter |

|---|---|

| Chuck (Standard) | ⌀200 3-Jaw Manual Chuck |

| Overall Dimensions (L×W×H) | 2350×1380×1640 mm |

| Net Weight | 1600 kg |

| Power Supply | 380V±10%, 50Hz±1%, 3-Phase AC |

Video

Quality Assurance & Service

Strict Quality Control

Each ALCK0640 undergoes rigorous testing before leaving the factory, including:

Laser Interferometer Calibration: Ensures positioning accuracy.

48-Hour Continuous No-Load Operation Test: Verifies machine stability and reliability.

Actual Workpiece Trial Cutting: Validates machining performance.

Five-Star Service System

24/7 Technical Support: Round-the-clock response with initial reply within 10 minutes.

On-Site Service Dispatch: Action plan confirmed within 1 hour, with engineer deployment within 1 business day.

Comprehensive Training: Full-scope training in operation, programming, and maintenance.

Spare Parts Guarantee: Ample stock of commonly used parts ensures fast supply.

Warranty Commitment

All machine tools are covered by a 12-month quality warranty, backed by lifelong maintenance service.

Why Choose ALLES CNC?

Professional Manufacturing Capability

ALLES CNC operates a modern production base covering 30,000 square meters, equipped with advanced machinery such as five-axis machining centers, gantry milling machines, and laser cutting machines. The entire production process—from casting to assembly—is independently controlled to ensure product quality.

Industry Certifications

ISO9001 Quality Management System Certification

EU CE Safety Certification

SGS Supplier Certification

Global Service Network

Our products are exported to over 30 countries and regions, including Europe, North America, and Southeast Asia. We have established a comprehensive overseas service network to provide localized support for our customers.

Get Your Customized Solution Now

The ALCK0640 flat-bed CNC lathe has successfully helped hundreds of enterprises improve production efficiency and product quality. Our engineers will provide the most suitable configuration and competitive pricing based on your specific needs.

Request Detailed Technical Materials and Quotation:

WhatsApp: +8615564169508

Email: cncfactory@allescnc.com

Address: Room 801, Building 2, Innovation Center, Zhangjin Comprehensive Bonded Zone, Jinan City, Shandong Province, China

Related Product Recommendations

Flat Bed CNC Lathe:

With its sturdy construction and high rigidity, this machine provides a cost-effective and versatile machining solution for medium and small disc-type and shaft-type components.

Slant Bed CNC Lathe:

Featuring a high-rigidity slant bed design, it ensures smooth chip removal and excellent dynamic response, making it ideal for precision machining that demands both high efficiency and accuracy.

CNC Pipe Thread Lathe:

Designed specifically for industries such as oil and gas, it excels in efficient and high‑precision turning and threading of various pipes, couplings, and complex thread profiles.

CNC Turning and Milling Machine:

Integrating turning, milling, drilling, and tapping functions, it enables multi‑face compound machining in a single setup, greatly improving the efficiency and precision of complex‑part production.

Vertical Machining Center:

Suitable for plate‑type, disc‑type, mold, and complex parts, it performs multi‑process precision milling, drilling, and tapping with a high degree of automation.