PRODUCT

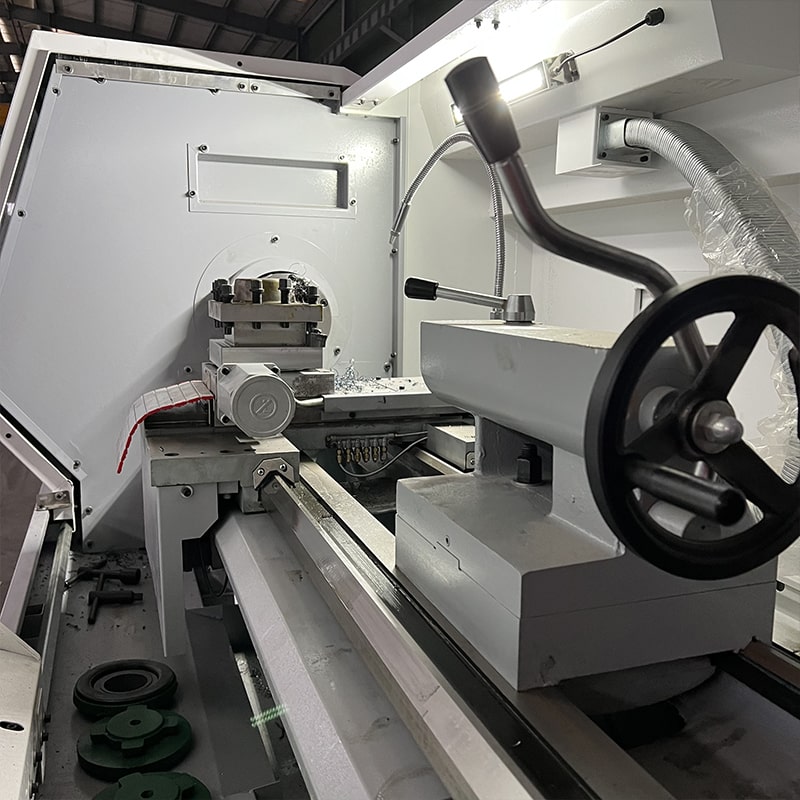

Automatic cnc lathe can process parts with high rigidity, high manufacturing precision, and shape accuracy requiring straightness, roundness, and cylindricity of the busbar.

CNC lathe ALCK6140 in the case of arcs and other curved profiles, the machining shape is closer to the geometric shape required by the customer.

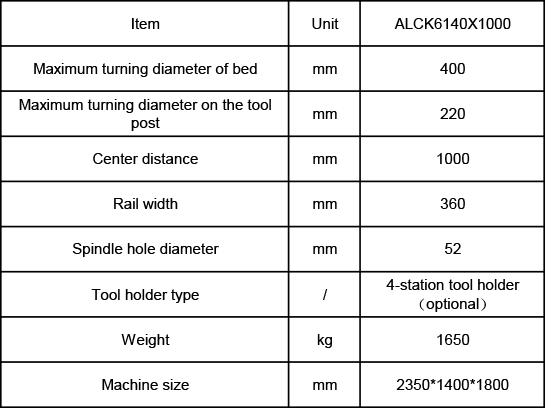

Product Parameters

Performance advantages of cnc lathe machine processing parts:

1. High productivity

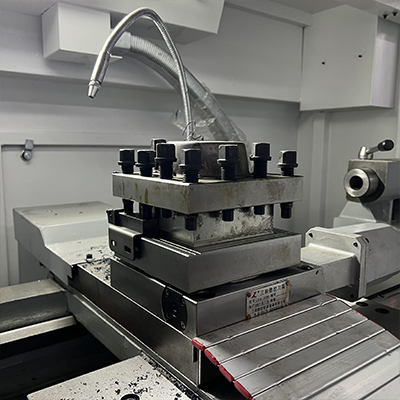

Continuous processing of multiple processes on a flat bed cnc lathe reduces the turnaround time between processes for semi-finished products and improves productivity.

2. Apply modernization of production management

CNC lathe turning can accurately estimate the processing time, standardize and modernize the tools and fixtures used, and facilitate the standardization of processing information.

3. The processing quality is stable and reliable

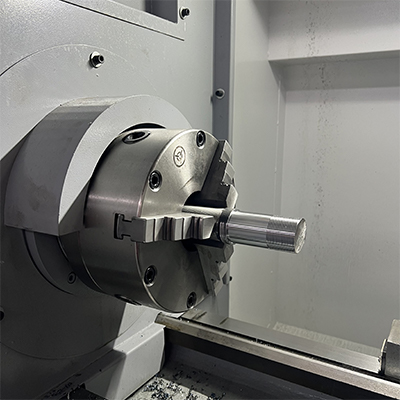

Processing the same batch of parts, in the same mini cnc lathe machine, under the same processing conditions, using the same tool and processing program, the cutting track of the tool is exactly the same, the consistency of the parts is good, and the quality is stable.

4. Improve working conditions

Horizontal cnc lathe is adjusted before processing, and the program is input and initiated, and the machine tool can automatically and continuously process until the processing is completed.

Metal cnc lathe application industry:

CNC lathe mainly meets the special needs of large and precision mold processing, precision parts processing, tapered hole or special-shaped hole processing and aerospace, aviation and other industries.