PRODUCT

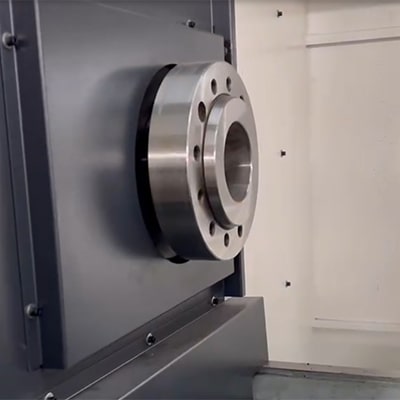

High precision cnc lathe can be created in a variety of shapes and sizes and is capable of creating both simple and complex parts. It is a versatile machining process that can create both small and large parts.

The cnc lathe machine is generally suitable for the production of medical equipment, auto parts, aerospace components, etc.

Aldoosanlecnc's CNC lathe features

1. Cnc lathe can combine machining steps by repositioning cutting tools to remove metal in different positions.

2. If equipped with a tool changer, the mini cnc lathe machine can switch between various styles of tools.

3. Combining operations like this can move a batch of parts through a machine shop in less time and save processing time.

4. The mini cnc lathe does not require operator input when machining metal.

This means that, for jobs with long cycle times, one operator can supervise multiple cnc mini metal lathes.

Application of CNC lathes in the automotive industry:

lathe machine mini cnc can be widely used in the prototyping and production of parts for the automotive industry.

Global automotive OEMs are finding more ways to optimize utilization of this process to deliver quality products to their customers and end customers.

cnc mini metal lathe machines are becoming more and more advanced to increase productivity levels, conduct self-diagnostic tests, demonstrate superior machinability, achieve compatibility with more materials, and more. In this way, CNC lathe turning extends automotive applications to a whole new level.

Additionally, the automation and shorter lead-time features of CNC horizontal lathe make it more profitable for most manufacturing-intensive units within the industry.

Video

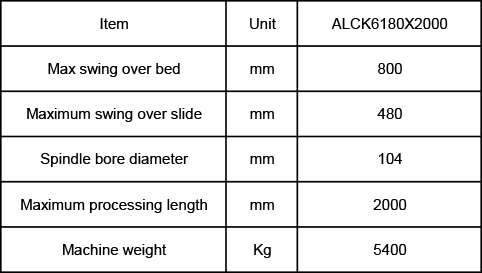

Product Parameters