PRODUCT

ALCK6180X2000 flat bed cnc lathe is a high-precision, high-efficiency, flexible and reliable processing equipment, widely used in automobile manufacturing, aerospace manufacturing, machinery manufacturing and other industries. Its advanced processing technology and high-quality processing effect of flat bed cnc lathe will bring wider application prospects. This article will introduce the application industry and characteristics of ALCK6180X2000 flat bed cnc lathe.

Features of heavy duty CNC lathe

1. High precision

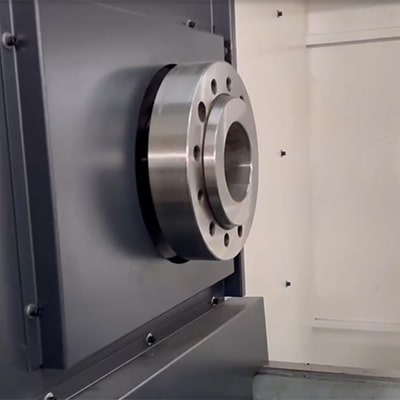

ALCK6180X2000 heavy duty CNC lathe adopts high-precision linear guide rail and precise spindle running system, which can realize high-precision machining effect, and the minimum machining accuracy can reach 0.001mm. At the same time, the CNC system can also monitor and adjust the errors in the machining process in real time, so as to ensure the stability and consistency of machining accuracy.

2. High efficiency

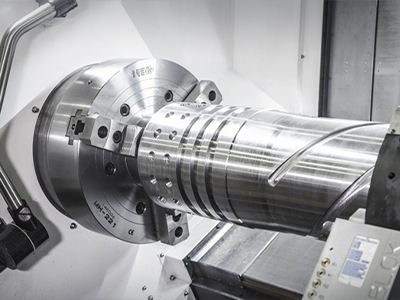

The heavy duty CNC lathe adopts an automatic control system, which can automatically complete various processing operations, so as to achieve high-efficiency production. At the same time, the CNC system can also automatically adjust parameters such as cutting speed and feed speed according to different processing requirements, so as to achieve high-efficiency production.

3. Flexibility

Heavy duty CNC lathe can realize the processing operation of different parts through program control. At the same time, the CNC system can also automatically adjust tools and cutting parameters according to different processing requirements, so as to achieve flexible production.

4. Reliability

ALCK6180X2000 heavy duty CNC lathe adopts a highly stable mechanical structure and control system, which can ensure the stability and reliability of the equipment. At the same time, the numerical control system can also monitor the operation status of the equipment in real time, find and eliminate faults in time, so as to ensure the normal operation of the equipment.

Application industries of horizontal CNC lathe:

1. Automobile manufacturing

The automobile manufacturing industry is one of the main application industries of horizontal CNC lathe. The processing of auto parts requires high precision and high efficiency, and horizontal CNC lathe can provide high-speed, high-precision processing effects, which greatly improves the production efficiency and product quality of the automobile manufacturing industry.

2. Aerospace Manufacturing

The aerospace manufacturing industry also requires high-precision component manufacturing. Due to the particularity of their application environment, these parts also need special properties such as high temperature resistance and corrosion resistance. And ALCK6180X2000 horizontal CNC lathe can meet these special needs with appropriate tool and cutting parameters, it is an ideal processing equipment for aerospace manufacturing industry.

3. Machinery manufacturing

Machinery manufacturing is one of the most widely used industries for horizontal CNC lathe. Horizontal CNC lathe can process parts of various materials, including metal, plastic, ceramic and so on. In the machinery manufacturing industry, horizontal CNC lathe has a wide range of applications, and can manufacture various parts such as tools, bearings, gears, and hydraulic components.

Video

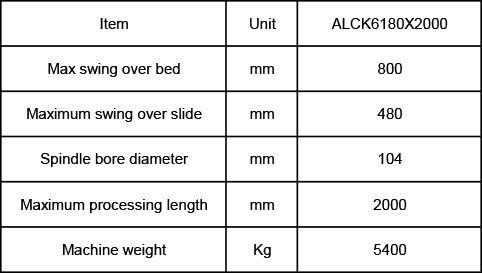

Product Parameters