PRODUCT

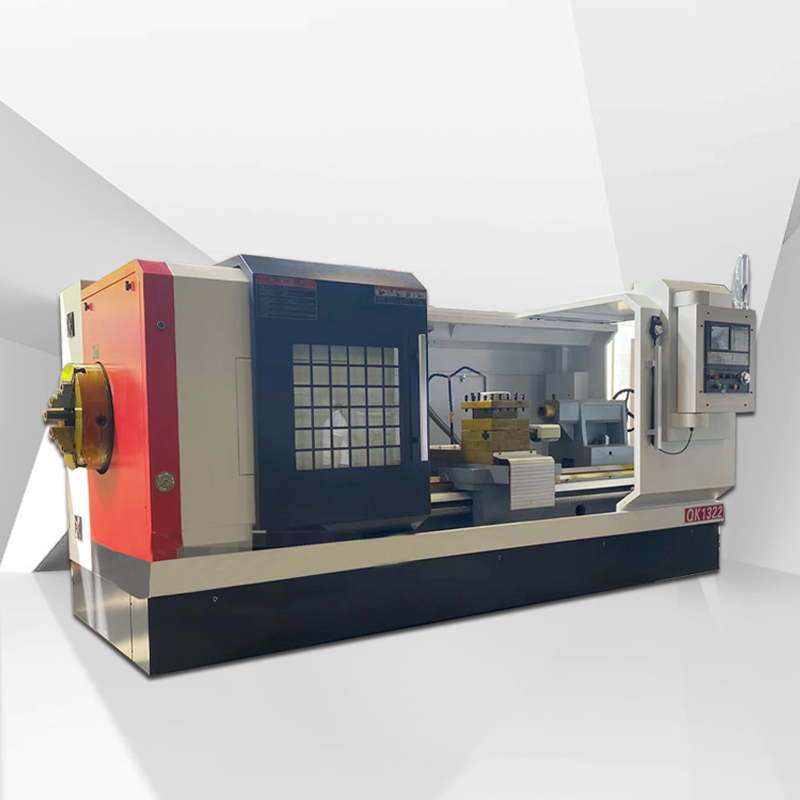

Using the sutomatic CNC pipe threading machine can efficiently complete the cutting of pipe joints, tie rods, casings, pipeline pipes, mine pipes, and water pump pipes.

CNC pipe threading lathe is suitable for processing tubing, casing, drill pipe, etc. in petroleum, metallurgy, chemical industry, hydropower, geological and other departments.

CNC pipe thread lathe adopts advanced numerical control system with high control precision and good reliability.

CNC lathe pipe thread lathe machine adopts PLC interface, which improves the reliability and control flexibility of CNC oil pipe lathe.

Product Features

1. CNC pipe threading lathe can process internal and external straight pipe threads and tapered pipe threads.

2. A taper device with a taper of 1:5 is installed on the CNC pipe thread lathe.

3. The cnc lathe pipe thread lathe machine can turn metric and inch threads without changing gears.

4. There is a shedding worm in the CNC Oil Lathe slide box, which can automatically protect the integrity of the lathe mechanism.

5. CNC turning machine guide rails are quenched and wear-resistant and finished.

6.High quality cnc lathe automatic has a large power and is capable of heavy-duty and powerful cutting.

7. Automatic CNC Pipe Threading Machine The floor-standing center frame can be moved freely according to the user's needs. The center frame is equipped with a long pipe clamping adjustment mechanism, thus greatly reducing the labor intensity.

8. There are four-jaw chucks on the front and rear of the CNC Oil pipe lathe head box, which are suitable for the desired clamping of long and short pipes.

What is the reason for the non-stop rotation of the CNC pipe threading lathe tool post?

1. Cause of failure: CNC pipe thread lathe tool post motor has no power supply. Check whether the power circuit of the knife post motor is open, whether the contacts are in good contact, and whether the high-voltage electrical components are damaged.

Solution: Check whether the fuse is blown.

2. Cause of failure: cnc lathe pipe thread lathe machine knife holder motor is damaged.

Solution: Remove the tool holder motor, turn the tool holder, and see if the motor rotates. If it does not rotate, replace the knife holder motor when the wiring is confirmed to be normal.

3. The cause of the failure: the CNC turning machine is stuck.

Solution: Turn the knife holder by hand, and judge whether it is stuck by the tightness. If so, remove the tool holder, adjust the machine and add lubricating fluid.

Video

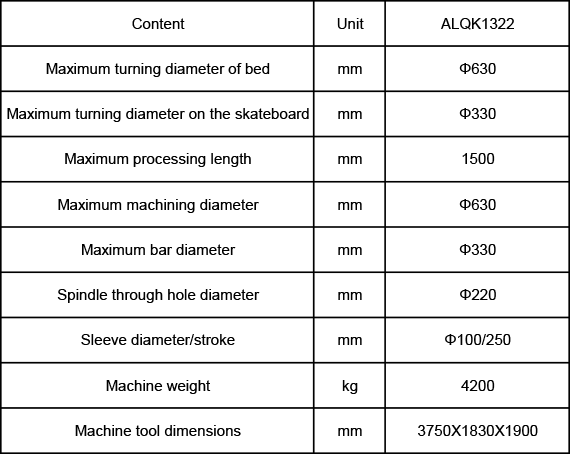

Technical Parameters