PRODUCT

Cnc pipe thread lathe is automatically controlled by the cnc system, which can accurately process various internal and external threads, and can also be used as an ordinary cnc lathe to process the outer circle, inner hole, end surface and conical surface of the workpiece.

Cnc lathe pipe thread lathe machine is very suitable for processing oil pipes, casings, drill pipes, etc. In petroleum, metallurgy, chemical, hydropower, geological and other departments.

Product Features of aldoosanlecnc

1. Cnc oil lathe has high degree of automation, high efficiency, good precision, wide application range and simple operation.

2. High quality cnc lathe automatic is my common lathe at present, and it is a boutique among medium-sized cnc lathes.

3. Automatic cnc pipe threading machine cnc system modular design, easy debugging, convenient maintenance, x, z axis adopts high-power, servo motor, advanced performance, strong reliability.

4. Cnc turning machine adopts casting bed saddle and skateboard, and the internal rib layout is reasonable.

CNC Oil pipe lathe technical requirements:

1. Satisfy the requirements of machine repair equipment and other related equipment quality management.

2. The structure and production of cnc pipe thread lathe should comply with the relevant national and industry standards, and the connection equipment between all accessories and the main body should be provided by the manufacturer.

3. The operating conditions of cnc lathe pipe thread lathe machine must adapt to the objective environment of equipment operation, and should meet relevant industry standards and various regulations.

4. Provide cnc oil lathe parameter information, product identification certificate, product model use certificate, technical data sheet and relevant technical information, and successful supply records of similar products.

Video

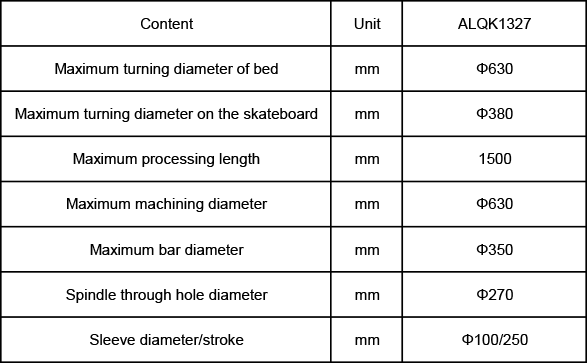

Technical Parameters