PRODUCT

High-precision CNC turning-milling machine has a wide range of applications and can be used to process workpieces of various shapes. It has the characteristics of high efficiency, high precision and multi-function, and is one of the indispensable important equipment in modern manufacturing.

Product Features:

1. Versatility: CNC turning and milling compound machine can realize various processing methods such as turning and milling, and can be used to process workpieces of various shapes, with high processing accuracy and surface quality.

2. High efficiency: metal cnc lathe has the functions of high-speed cutting and high-speed movement, which can greatly shorten the processing time and improve production efficiency.

3. High degree of automation: CNC lathe machine has the characteristics of high degree of automation, which can realize functions such as automatic loading and unloading, automatic tool change, automatic detection, etc., which can greatly improve production efficiency and processing quality.

4. Good flexibility: The processing program of cnc lathe turning can be modified through programming, which can adapt to the processing requirements of different workpieces and has good flexibility.

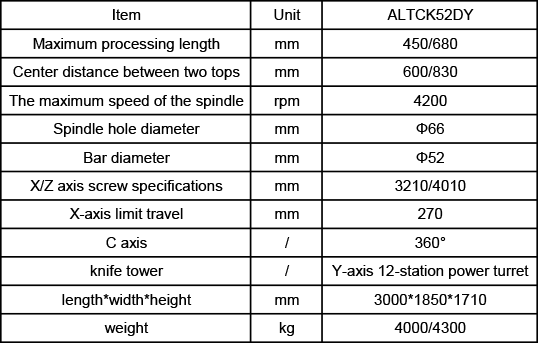

Technical Features:

High precision cnc lathe has a wide range of applications in the following fields:

1. Automobile manufacturing field: It can process auto parts, such as engine block, chassis components, transmission, steering gear, etc.

2. Medical device field: It can process various medical device parts, such as artificial joints, dental restoration appliances, cardiac pacemakers, etc.

3. Other fields: It can process various structural parts, molds, fixtures, military equipment, etc.