PRODUCT

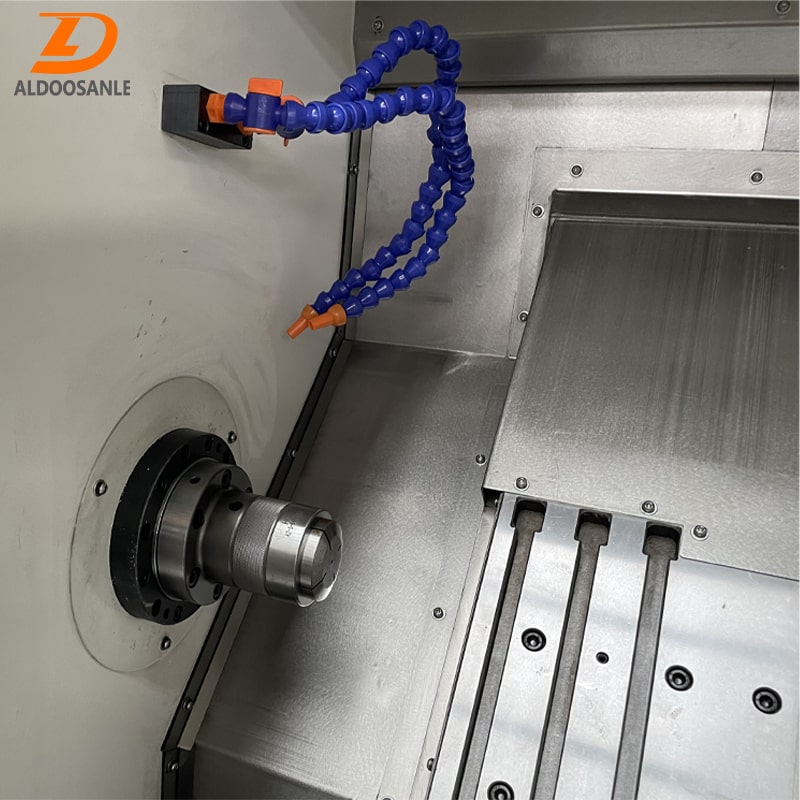

Small cnc lathe with bar feeder is a high precision and high efficiency cnc mini lathe with digital information control parts and tool displacement function. 4 axis cnc lathe machine live tooling is an effective way to solve the problems of aerospace products, such as many types of parts, small batches, complex shapes, high precision, high efficiency, and automatic processing.

Product Features

1.cnc lathe fanuc eases the labor efficiency of employees and improves the office environment.

2. One person can watch several 3 axis cnc lathes, saving financial and material resources.

3. It only needs manpower to pour the product workpiece into the automatic feeding mechanism such as the vibrating plate, and then the automatic processing of the product workpiece can be carried out, eliminating human factors such as mentality and other hazards.

4.Lathe machine cnc processing is highly efficient, and the automatic clamping speed is faster.

5. Double spindle cnc lathe can complete 24 hours of uninterrupted processing.

What should I do if Automatic CNC Lathe is prone to deformation when processing thin-walled products?

This kind of product is a bit difficult, and some may have to be divided into many processes to complete. You can analyze and judge according to the product requirements!

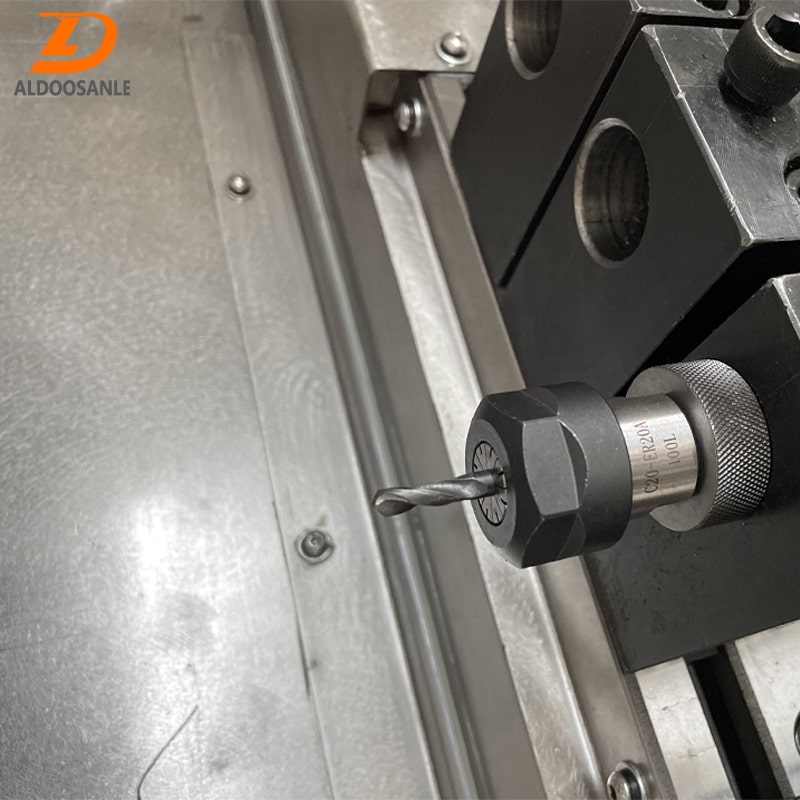

Be sure to use low speed, slow feed, and less back to eat the three major processing elements! And it is necessary to use a tool with a small tip and a relatively sharp blade, and the clamping should also be axial clamping (such as pressing a screw sleeve) as much as possible. If radial clamping is used, it will always be deformed!

Video

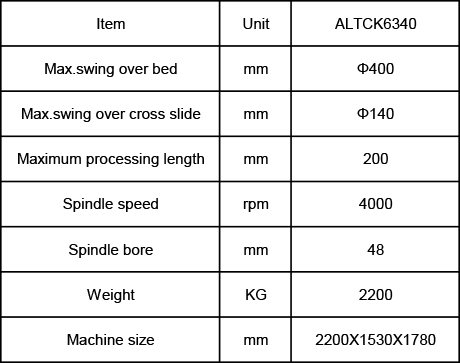

Product Parameters