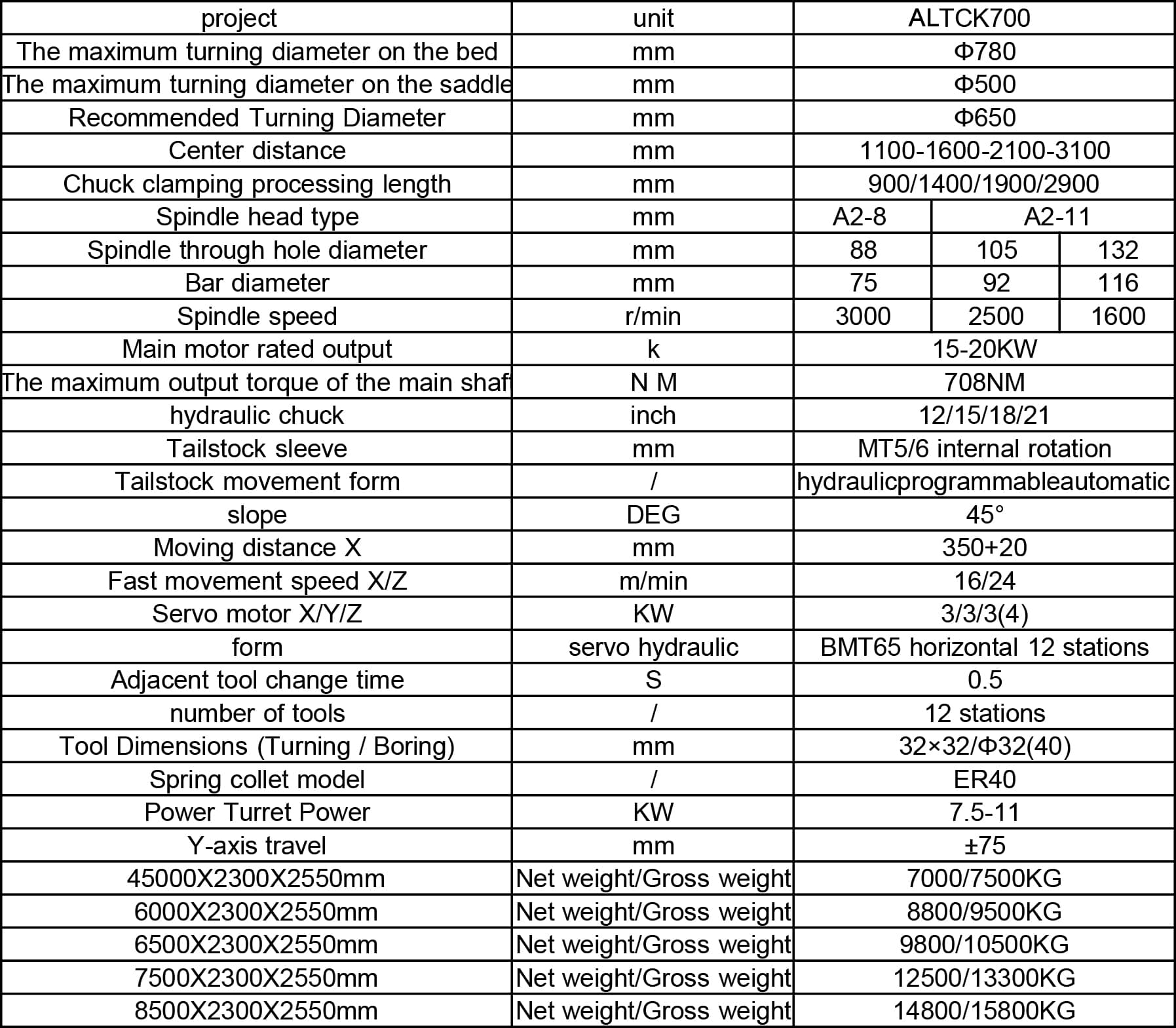

PRODUCT

CNC turning and milling machine ALTCK700X1500: Features and applications

The CNC turning and milling machine ALTCK700X1500 is an advanced CNC machine tool with many features and is widely used in various industrial fields. This article will introduce the main features of ALTCK700X1500 and its important role in different application industries.

The CNC turning and milling machine ALTCK700X1500 has become an indispensable production tool in many industrial fields due to its high precision, versatility and automation features. It not only improves production efficiency, but also improves product quality and helps promote the development of manufacturing.

Features of CNC turning and milling machine:

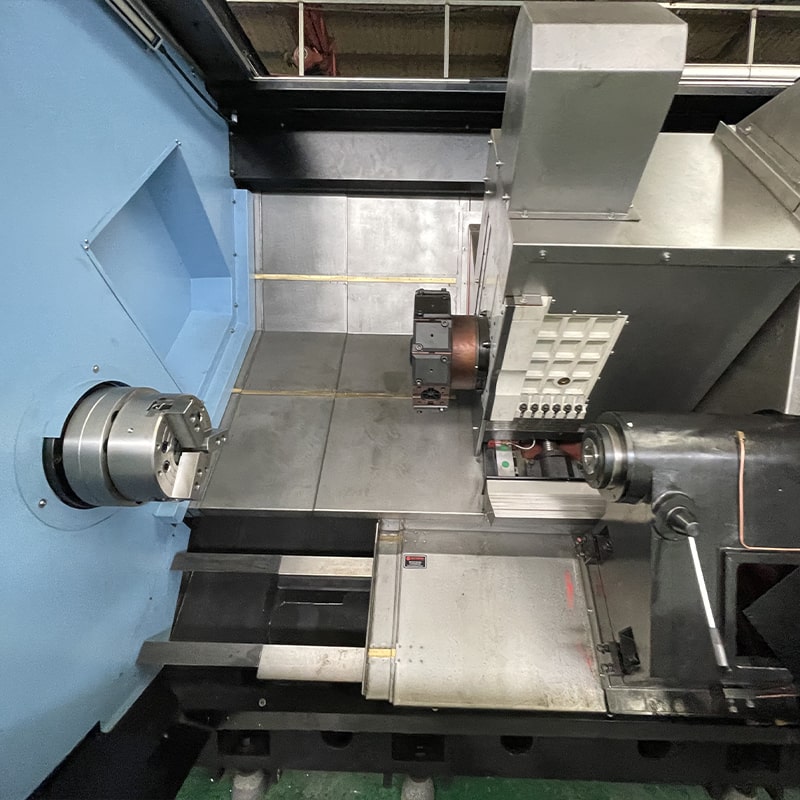

1. High-precision processing: ALTCK700X1500 CNC turning and milling compound machine adopts advanced CNC technology to achieve high-precision processing and ensure product quality and accuracy. This makes CNC mill-turn machines popular in industries that require precision parts, such as aerospace, automotive manufacturing, and medical device manufacturing.

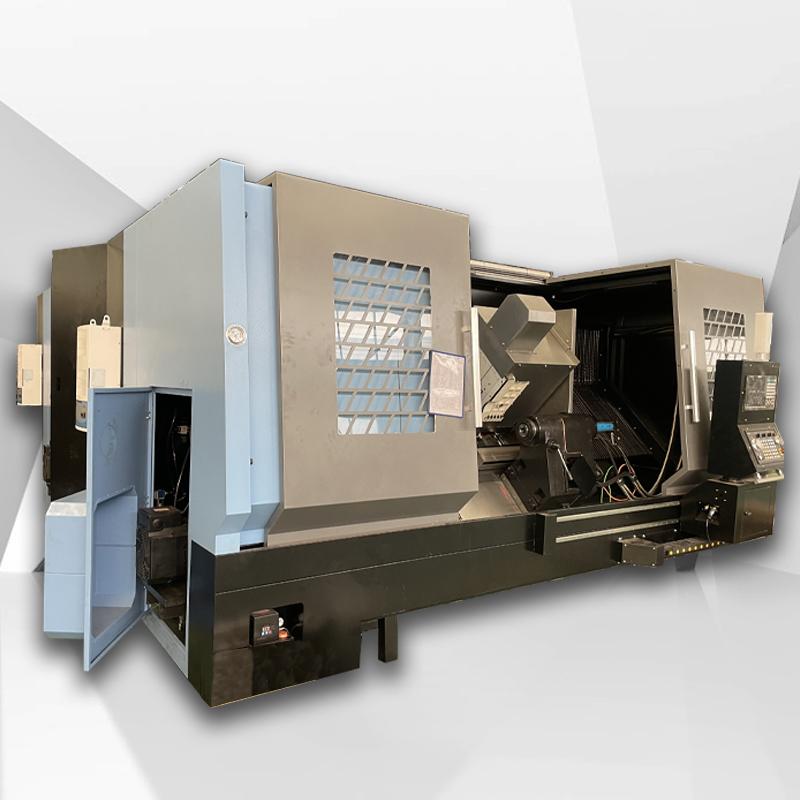

2. Versatility: This machine tool has the combined processing capabilities of a lathe and a milling machine. Operators can easily switch working modes, thereby increasing productivity and reducing equipment footprint and costs.

3. High degree of automation: ALTCK700X1500 CNC turning and milling compound machine is equipped with advanced equipment such as automatic tool changing system, automatic workpiece clamping system and automatic tool measurement system, which makes the production process more automated, reduces labor demand and reduces human errors.

4. High cutting speed: CNC turning and milling compound machines are equipped with high-performance spindles and cutting tools, which can achieve high-speed cutting, improve production efficiency, and are especially suitable for mass production.

5. User-friendly interface: This CNC machine tool has an intuitive user interface, is easy to operate, and is easy for novices to use. This means more operators can quickly master the operation of the machine tool, providing more flexibility for production.

Application industries of CNC turning and milling compound machines:

1. Aerospace industry: CNC turning and milling machine ALTCK700X1500 is widely used in the aerospace field to manufacture aircraft parts, such as engine parts, aviation bearings, etc. Its high precision and high cutting speed make it ideal for manufacturing advanced aircraft.

2. Automobile manufacturing industry: In the automobile manufacturing industry, this machine tool is used to process key components such as automobile engines, transmissions, and chassis components. Its high efficiency and versatility help meet the automotive industry's demand for high-quality components.

3. Medical equipment manufacturing industry: The manufacturing of medical equipment requires high precision. The CNC turning and milling machine ALTCK700X1500 can be used to process various parts of medical equipment, such as artificial joints, surgical tools, etc., to ensure its accuracy and quality.

4. Mold manufacturing industry: Due to the high-precision processing capabilities of the ALTCK700X1500 CNC turning and milling compound machine, it is very popular in the mold manufacturing industry. Mold manufacturing requires highly precise processing to ensure the quality of the final product.

5. Shipbuilding industry: This machine tool is also widely used in the field of shipbuilding for processing ship hull structures, propulsion systems and marine equipment.

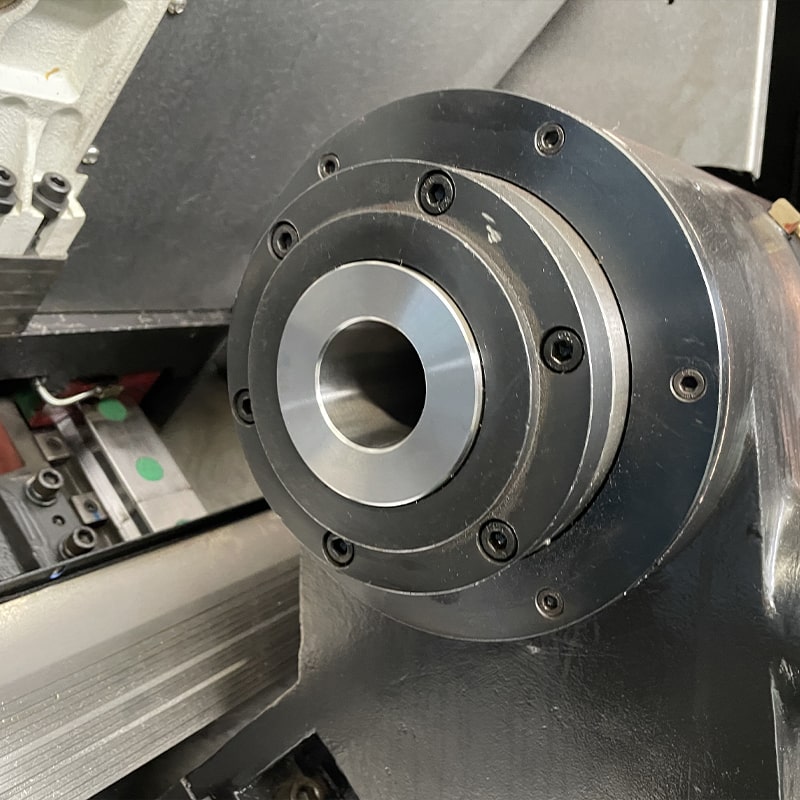

Technical Parameters