PRODUCT

ALVMC650 CNC vertical machining center, as an advanced CNC machining equipment, has a wide range of applications and excellent features. Whether it is in aerospace, automobile manufacturing, mold manufacturing or general machining industries, ALVMC650 CNC vertical machining center has demonstrated its efficient, precise and multi-functional machining capabilities. This article will introduce the advantages of ALVMC650 CNC vertical machining center in the application industry and its own characteristics.

Application industries of Vertical CNC milling machine:

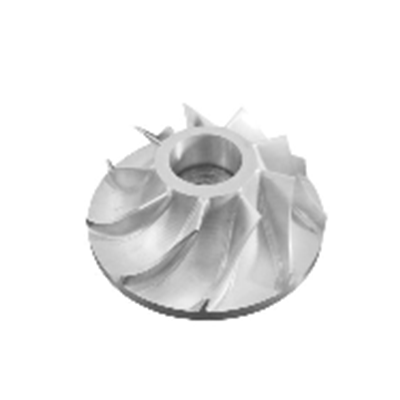

1. Aerospace industry: ALVMC650 Vertical CNC milling machine is widely used in aerospace field. Vertical CNC milling machine can process key components such as aircraft structural parts, engine parts, and avionics equipment. Due to its high-speed cutting, high-precision machining and complex contour machining capabilities, the ALVMC650 Vertical CNC milling machine is ideal for high-quality and efficient production in the aerospace industry.

2. Automobile manufacturing: ALVMC650 Large CNC machining center plays an important role in automobile manufacturing. The Large CNC machining center can process key components such as engine parts, chassis components, and body structural parts. Its high-speed machining, multi-axis cutting and automatic tool changing system enable ALVMC650 Large CNC machining center to meet the demands of precision machining, high quality and high production efficiency in the automotive industry.

3. Mold manufacturing: ALVMC650 Horizontal machining center is widely used in mold manufacturing. Horizontal machining center can process various complex mold parts, including injection molds, die-casting molds, stamping molds, etc. ALVMC650 Horizontal machining center provides high-precision machining capabilities, multi-functional cutting and high-speed cutting, making it an ideal equipment for improving production efficiency and ensuring machining quality in the mold manufacturing industry.

4. General machining industry: ALVMC650 Precision machining center is suitable for the manufacture of various parts in the general machining industry. Whether it is shaft parts, flanges or various connectors, ALVMC650 Precision machining center can provide efficient and accurate machining solutions to meet the diverse needs of the general machining industry.

Features of Industrial CNC machining center:

1. High speed and high efficiency: ALVMC650 Linear way machining center is equipped with high-power spindle and high-speed feed system, which can realize fast and precise cutting

2. High-precision machining: ALVMC650 vertical machining center adopts advanced numerical control technology and precise transmission device, which has excellent machining accuracy and repeat positioning accuracy. Whether it is processing complex curved surfaces, small apertures or precision parts, ALVMC650 CNC metal milling machine can provide accurate processing results.

3. Multi-axis cutting capability: ALVMC650 High-efficiency machining center has multi-axis cutting function, which can realize one-time processing of complex parts.

4. Automation and intelligence: ALVMC650 CNC metal milling machine adopts advanced automation control system, which supports functions such as automatic tool change, automatic workpiece measurement and automatic compensation. At the same time, the CNC vertical machining center also has an intelligent programming and monitoring system, the operator can easily program, adjust parameters and monitor the machining process to improve production efficiency and operational convenience.

5. Strong and stable structure: ALVMC650 Machining center CNC adopts high-quality cast iron bed and optimized mechanical structure design, which has excellent rigidity and stability. This design can effectively suppress vibration and resonance phenomena, and ensure the stability and machining accuracy of the machining process.

Video

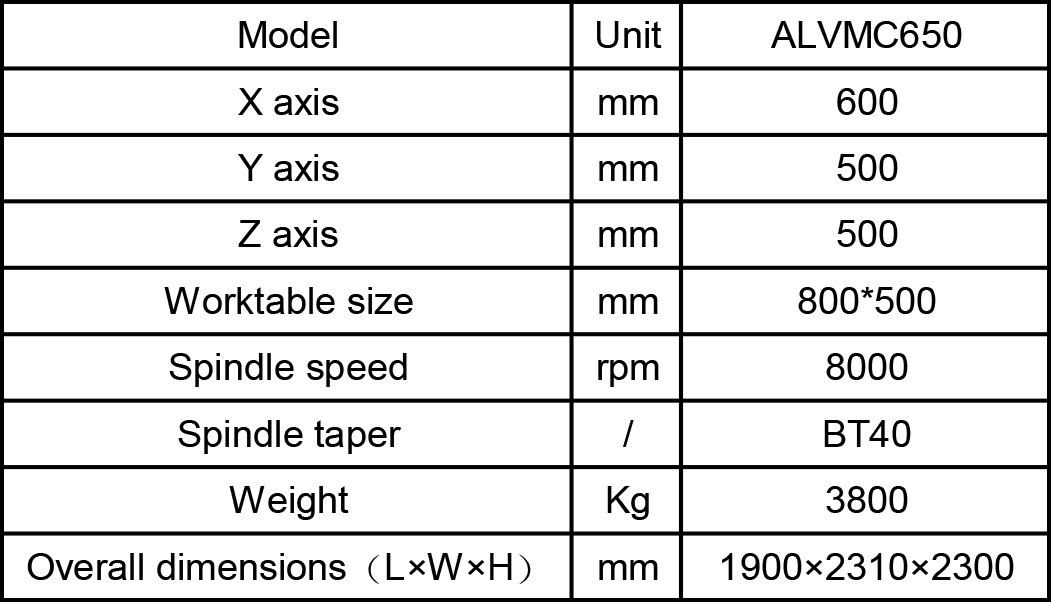

Technical Parameters