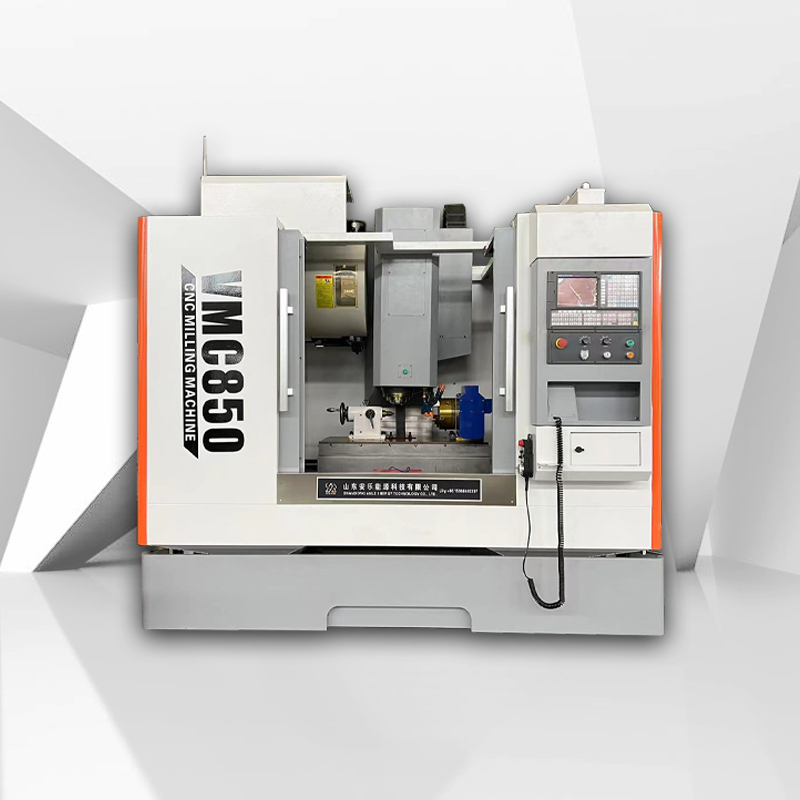

PRODUCT

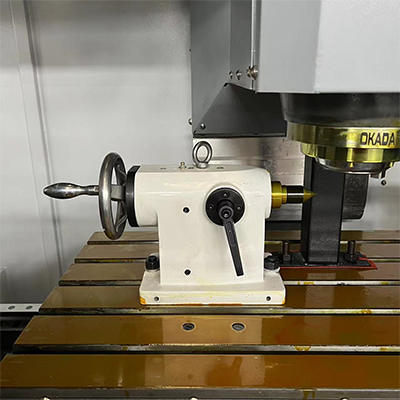

In the field of manufacturing, the application of CNC machine tools is becoming more and more popular. Among CNC machine tools, the 4-axis vertical machining center ALVMC850 has become a machine tool that has attracted much attention. The characteristics of high precision, high efficiency, high reliability and high stability of the Vertical machining center make the Vertical machining center play an increasingly important role in the manufacturing industry.

Features of high precision CNC machining center:

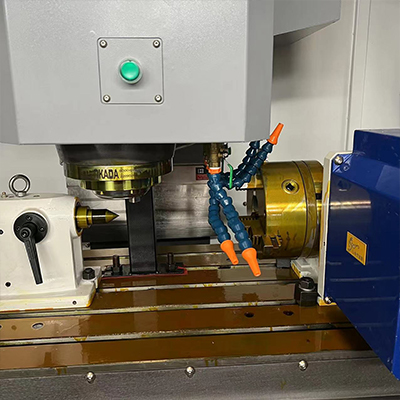

1. High precision: 4-axis CNC metal milling machine ALVMC850 adopts high-precision linear guide rail and precision ball screw, which can realize high-precision machining, and the precision can reach 0.005mm.

2. High efficiency: 4-axis CNC metal milling machine ALVMC850 adopts high-speed spindle, which can realize high-speed cutting and improve processing efficiency.

3. High reliability: 4-axis CNC metal milling machine ALVMC850 uses high-quality machine tool materials and advanced manufacturing technology to ensure the long-term stability and reliability of the machine tool.

4. High stability: 4-axis Vertical CNC milling machine ALVMC850 adopts high-rigidity machine tool structure and optimized machine tool design, which ensures the stability of the machine tool during processing.

Application industries of Large CNC machining center

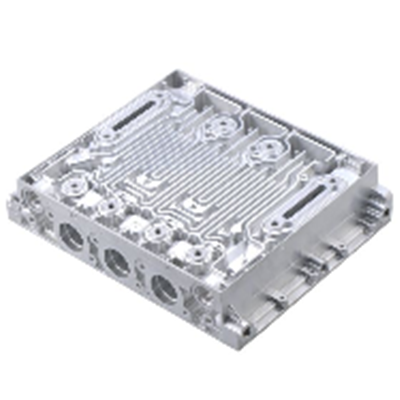

4-axis Precision machining center ALVMC850 is widely used in mold processing, auto parts processing, aerospace parts processing, precision machining and other fields. Among them, mold processing is one of the main application industries of 4-axis Automated machining center ALVMC850. With the continuous development of modern manufacturing industry, the precision and efficiency requirements for mold processing are getting higher and higher, and the 4-axis vertical machining center ALVMC850 is one of the machine tools that can meet such high requirements.

Video

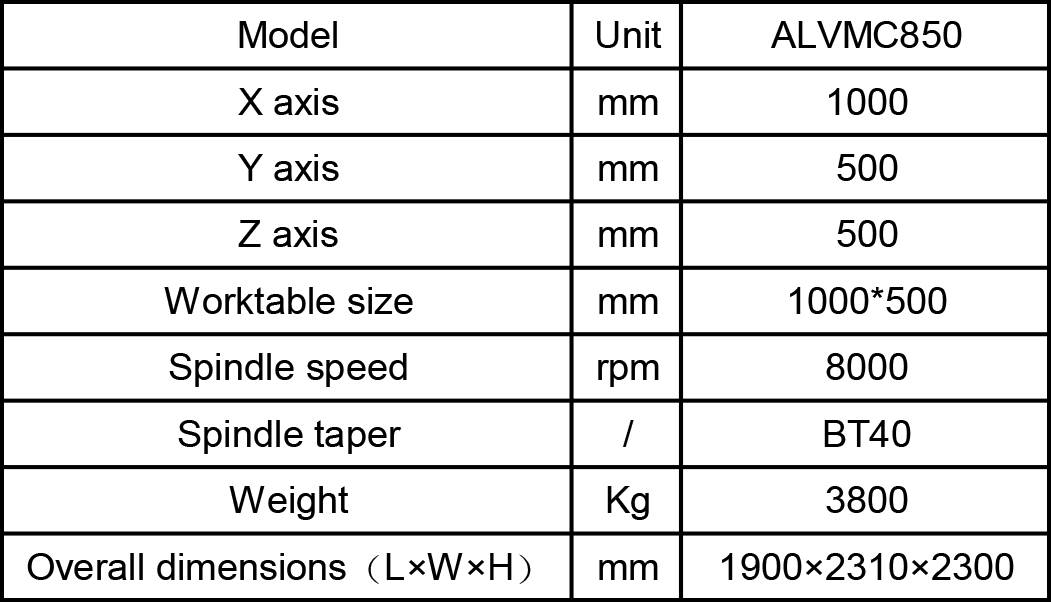

Technical Parameters