INDUSTRY NEWS

Briefly understand the characteristics of the small cnc lathe machine

The high precision cnc lathe realizes the synchronous rotation processing of the main/sub-axis, which not only solves the processing of the back of the part, but also further improves the processing efficiency.

Aldoosanlecnc's ALCK6130 flat bed cnc lathe machine can automatically complete the turning, front drilling, front tapping, front boring, threading, grooving, transverse drilling, Milling, slot milling, radial tapping, cutting off, back turning, back drilling, back boring, back tapping and many other compound processing operations.

Product Features

1. The cnc lathe machine is equipped with a numerical control system as standard, adopts a hardware platform, runs faster, ensures high-speed and high-efficiency processing, and has quadratic curve interpolation, ellipse interpolation, parabolic interpolation, groove machining cycle commands, and automatic tool compensation. and other functions. cnc lathe front USB interface, front communication interface, support U disk file operation and software upgrade, can be equipped with other mainstream CNC systems according to user needs;

2. The mini cnc lathe machine uses 220 volts of voltage, adopts transparent plexiglass and metal sheet metal fully enclosed structure, improves the safety and observation of use, and is cast with selected high-quality cast iron materials. Grinding, high hardness, good rigidity, to ensure the rigidity of the machine, using high-precision grinding ball screws to ensure machining accuracy, XZ axes are equipped with a centralized lubricating oil circuit system to ensure the service life and machining accuracy of the screw and guide rails ;It can automatically turn various revolving surfaces, such as cylindrical surface, conical surface, special-shaped surface, etc., and can perform threading, boring and reaming processing, with high efficiency and strong applicability;

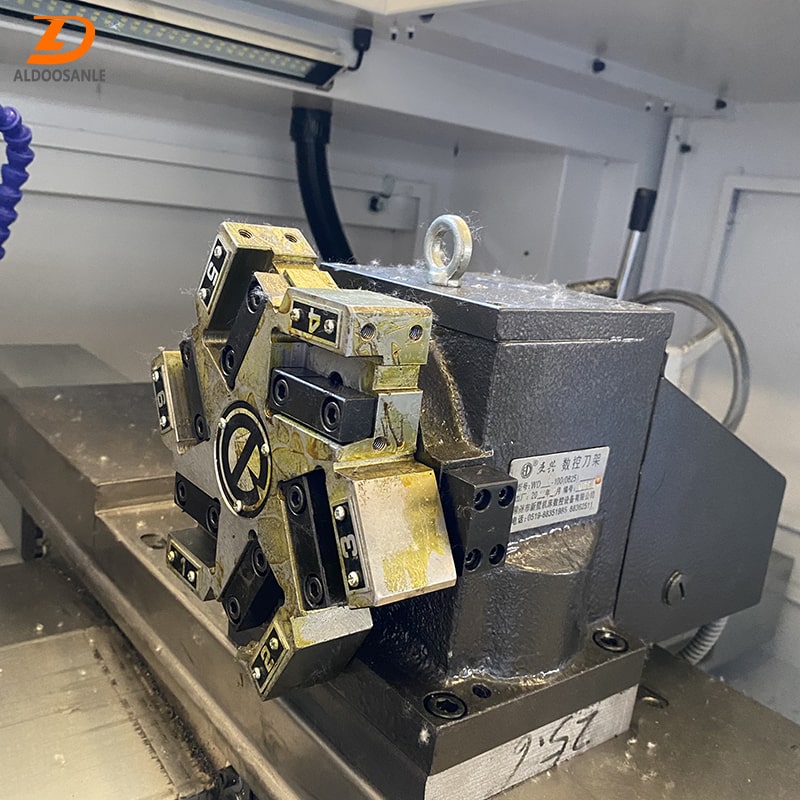

3. The mini cnc lathe is equipped with a workpiece cooling system, which can process steel parts; it is equipped with a 4-station electric tool rest, which can process complex parts technology;

4. The cnc mini metal lathe is equipped with electronic handwheel (manual pulse), manual operation and knife setting operation are more convenient and flexible, and it is equipped with Led work light;

5. The lathe machine mini cnc numerical control system has a graphic simulation function, a color LCD screen, which displays the graphics of the processing program and the tool movement trajectory during actual operation, and has a perfect self-diagnosis function. It can display an abnormality and immediately alarm in real time to ensure operational safety;

6. The cnc mini metal lathe machine adopts ISO standard G code programming, supports M code and S code, and is fully compatible with FANUC, G code and various CAD/CAM software (MasterCAM, UG, CAXA and other software programming, etc.); supports powerful B The macro analysis function is convenient for users to develop their own motion control programs;

7. The main processing materials of CNC lathe turning are: steel, iron, copper, aluminum, PVC plastic and other materials;

8. The CNC horizontal lathe is equipped with instructional teaching materials, and various processing consumables can be provided according to user needs;

9. The automatic cnc lathe has overload protection, short-circuit protection and leakage protection devices, which can automatically act in the event of abnormal voltage or short-circuit to protect personal and equipment safety;

10. The positioning accuracy of high precision cnc lathe is detected by laser interferometer.