PRODUCT

CNC lathe manufacture processing is aimed at some basic parts processing. The processed products are mainly used in communication fasteners, computer fasteners, home appliance fasteners, electrical fasteners, building materials joints, mobile phone fasteners, mobile phones, laptop computers, various plastic shells, Communications, micro motors, computers, electrical appliances, electronics, toys, watches, lighting, locomotives.

Product Features

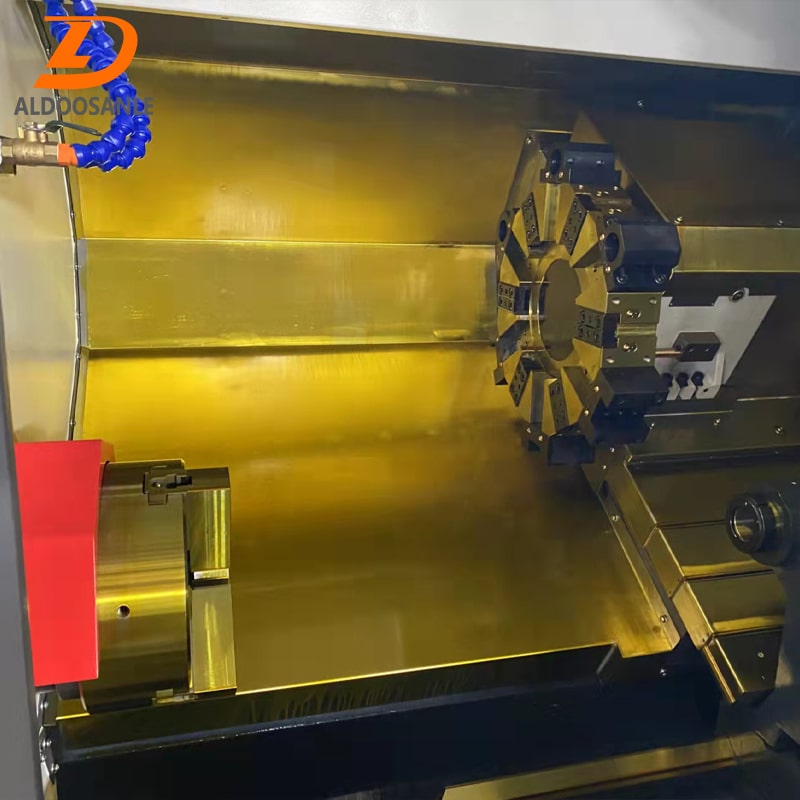

1. The horizontal cnc lathe machines have high machining accuracy, stable machining quality, multi-coordinate linkage, and complex shape parts machining;

2. When the machining parts of mini cnc lathe are replaced, generally only the CNC program needs to be changed, which can save production preparation time;

3. The cnc automatic lathe machine has high precision and good rigidity, can choose favorable processing volume, and has high productivity (three to five times faster than ordinary lathe processing parts);

4. The cnc metal lathe spindle machine has a high degree of automation, which can reduce labor intensity; it has higher requirements for the quality of operators and higher technical requirements for maintenance personnel.

Product application

With its high degree of flexibility and programmability, turning machine cnc lathe is able to perform many complex processes, including:

1. Turning: The cnc lathe machine metal horizontal cutting tool is mounted on a moving slider, as the workpiece rotates, the tool is pressed against the workpiece, and the slider moves up and down along the workpiece, and away from or close to the centerline. Turning processes are often used when large amounts of material need to be removed quickly from a workpiece.

2. End face: In the end face, the single-point tool moves along the workpiece, removing a thinner layer of material. This process produces a flat, smooth surface at the end of the workpiece.

3. Thread cutting: Here, the tool of high precision cnc lathe moves along the outside of the workpiece to create threads on the outer surface. These threads can be cut to any length or pitch.

4. Slotting: The tool of the mini metal lathe machine moves along the workpiece, and gradually cuts out a groove that matches the width of the tool. Multiple passes may be required to get wider grooves or add various geometries.

5. Tapping: This cuts a thread into the hole so the screw can be screwed into it.

6. Taper: The metal lathe mini produces a taper on the workpiece.

7. Knurling: The metal lathe machine forms indentations on the edge of the workpiece.

8. Chamfering: Remove burrs and create a bevel on the end of the workpiece for a better appearance.

Video

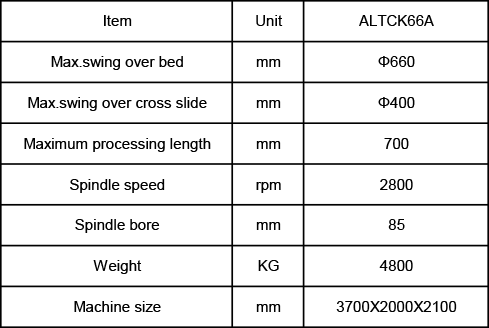

Product Parameters