PRODUCT

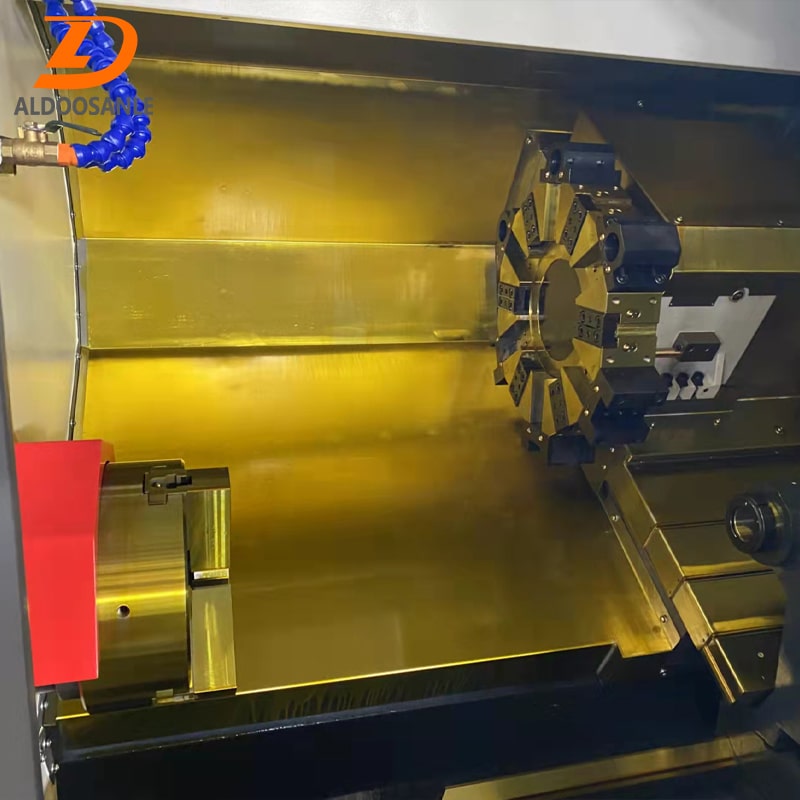

Slant bed cnc lathe machine ALTCK66A adopts a one-piece slanted bed with low center of gravity and excellent rigidity. They can withstand heavy cuts while maintaining precision. Electrical cabinet heat exchangers keep components within safe temperatures, extending their life and reducing downtime.

CNC slant bed lathe machine is suitable for precision machining of various high-precision, multi-batch and complex-shaped parts in aviation, electronics, clock and watch industries,

Product features of Aldoosanle cnc

1. CNC lathe can be equipped with hydraulic chuck and tailstock, which can realize automatic loading and unloading.

2.CNC lathe machine selected system and functional parts can be clamped at one time to realize turning and milling functions.

3.Metal slant bed cnc lathe machine can meet the rough machining and finishing machining of various high-temperature alloys, titanium alloys, heat-resistant alloys, stainless steel, cast iron, cast steel and other materials.

4. Castings are tempered to eliminate internal stress, X and Z-axis guide rails adopt linear guide rails, and the straightness correction of the whole stroke ensures the movement of the machine tool and maintains good precision.

6. The spindle speed of CNC lathe machine slant bed is higher.

Application of Mini cnc lathe machine:

CNC machining is a manufacturing process used in a variety of industries including automotive, aerospace, construction and agriculture.

CNC processing technology is applicable to a variety of engineering materials, including metals (such as aluminum, brass, stainless steel, alloy steel, etc.), composite materials, etc.

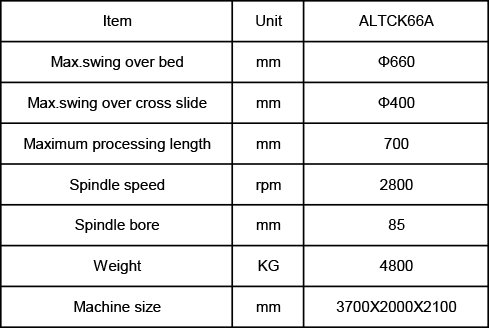

Product Parameters