PRODUCT

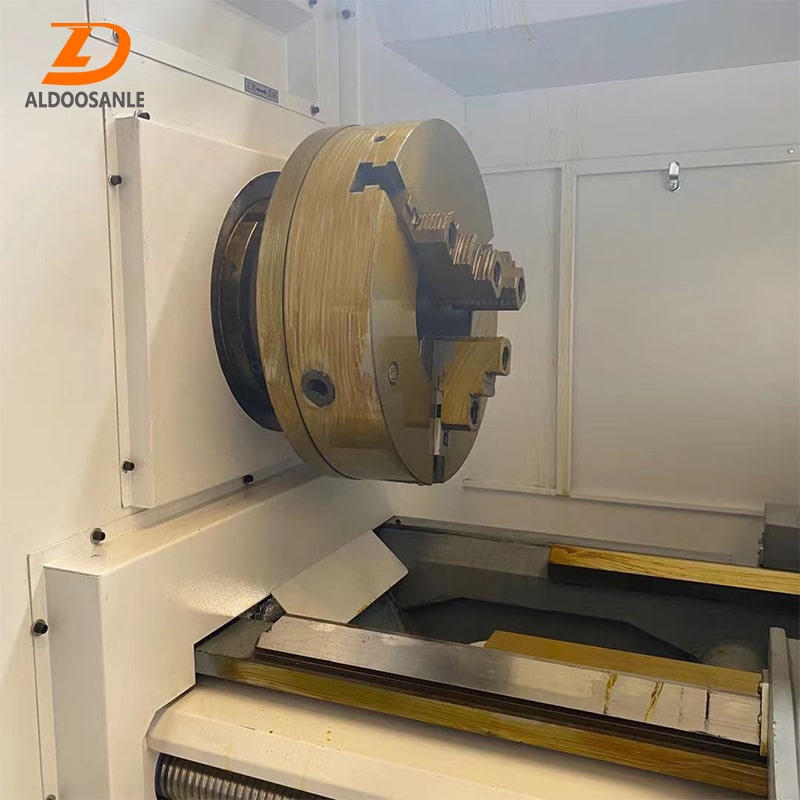

CNC pipe threading lathe ALQK1332 for petroleum equipment

We specially developed CNC pipe threading lathe according to the needs of the petroleum industry. Users can choose different specifications of CNC pipe threading lathe to process oil casing, oil casing coupling and oil drill pipe joint according to their needs.

CNC lathe pipe thread lathe machine is a high-precision, high-efficiency inclined bed automatic machine tool, equipped with advanced configurations such as multi-station servo or power turret, which can process cylinders, arcs and various threads, and can process complex workpieces.

High quality cnc lathe automatic plays a great role in the petroleum equipment industry.

In CNC pipe threading lathe processing, what factors will affect the appearance quality of processing?

(1) The performance of CNC pipe thread lathe processing

The first is the wear resistance, corrosion resistance and fatigue strength of the cnc lathe pipe thread lathe machine equipment. The better the wear and corrosion resistance, the better the resistance to deformation and corrosion, which in turn prevents severe wear. Good fatigue strength can delay the occurrence of fatigue damage and avoid affecting its appearance quality.

(2) CNC Oil Lathe processing physical and mechanical properties

The first two aspects are the microstructure change of the external data and the external residual stress. Generally speaking, the stronger the plasticity of the workpiece data, the more obvious the chill phenomenon will be.

Application of CNC pipe threading lathe

CNC pipe threading lathe processing mainly cuts off most of the pipe thread machining allowance, and does not require high pipe thread machining accuracy.

Therefore, rough pipe threading should be performed on high-power, low-precision CNC pipe thread lathe, while fine pipe threading requires high-precision CNC lathe pipe thread lathe machine.

Coarse pipe threading and fine pipe threading are carried out on different CNC Oil Lathes, which not only makes full use of the equipment's capabilities, but also prolongs the service life of precision CNC turning machines.

Video

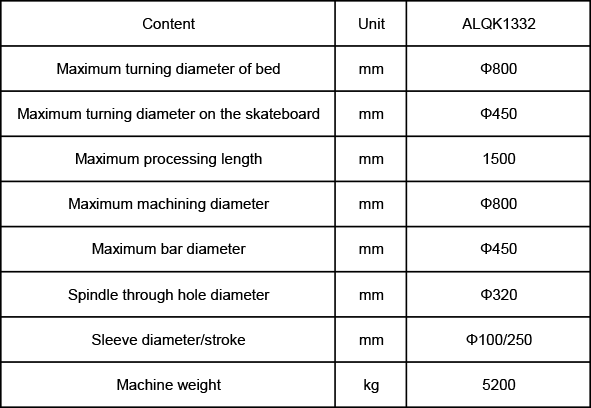

Technical Parameters