PRODUCT

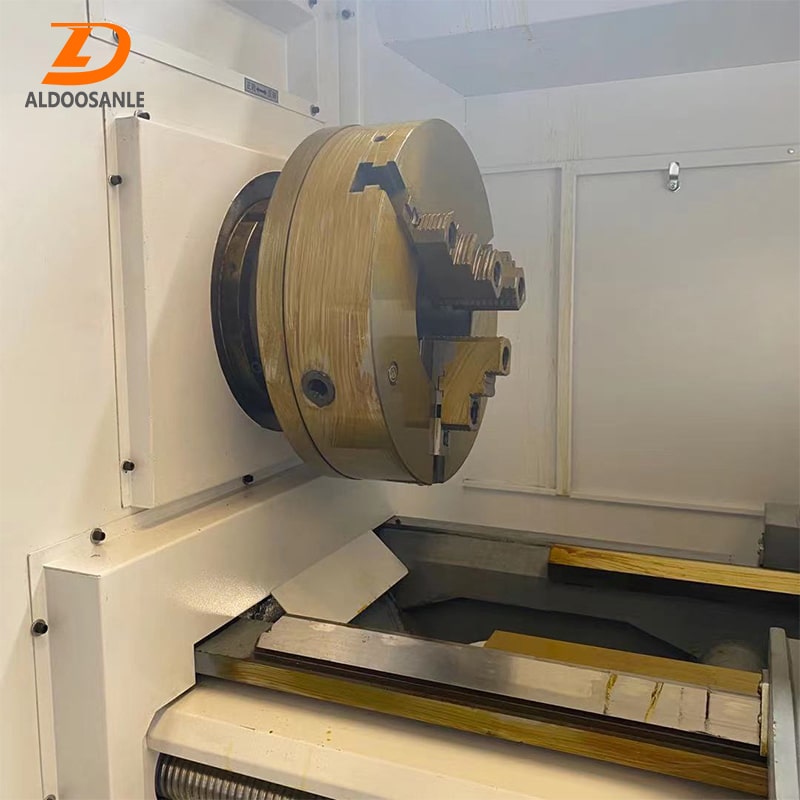

CNC pipe thread lathe has high precision, high efficiency and good anti-seismic performance, cnc lathe pipe thread lathe machine has beautiful appearance, reliable safety device, and good amenity.

The main movement of CNC Oil Lathe adopts electromagnetic brake, the brake is sensitive and the noise is low. The modular design of CNC turning machine numerical control system is easy to debug and maintain. The x and z axes adopt high-power servo motors with advanced performance and strong reliability.

High quality cnc lathe automatic is suitable for oil, machine tool, hydraulic, ship. locomotive. High-efficiency, high-volume, high-precision processing of rotating workpieces in aerospace, metallurgy and other industries.

Notes on the operation of Automatic CNC Pipe Threading Machine:

1. It is strictly forbidden for non-staff personnel to operate CNC Oil pipe lathe.

2. It is strictly forbidden to touch the tool, the rotating part of the CNC pipe threading lathe or the rotating workpiece during operation.

3. Do not use emergency stop. In case of emergency, after using this button to stop, you should check again according to the regulations before starting the CNC pipe thread lathe.

4. It is not allowed to step on the guide rail surface of cnc lathe pipe thread lathe machine, screw rod, polished rod, etc., and it is not allowed to use feet instead of hands to operate the handle except for regulations.

5. For parts with trachoma, shrinkage cavity or keyway on the inner wall, it is not allowed to scrape the inner hole with a triangular scraper.

6. The compressed air or liquid pressure of the hydraulic chuck after pneumatic operation must reach the specified value before it can be used.

7. For turning slender workpieces, when the length of the two sides in front of the CNC Oil Lathe bed exceeds 4 times the diameter, it should be used according to the process regulations. Center frame or heel frame support. When protruding behind the head of the bed, guards and warning signs should be added.

8. When high quality cnc lathe automatic is cutting brittle metal or cutting easy to splash (including grinding), a protective baffle should be added, and the operator should wear protective glasses.

Video

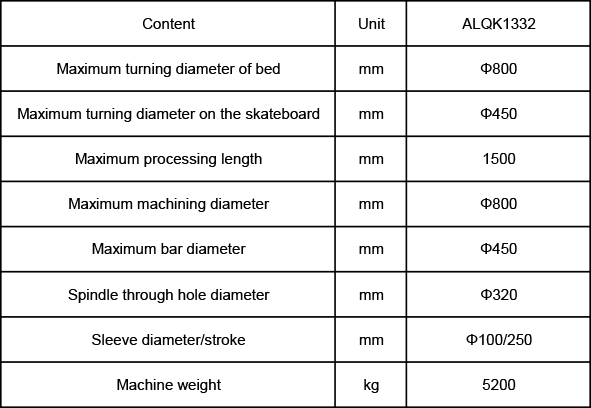

Technical Parameters