PRODUCT

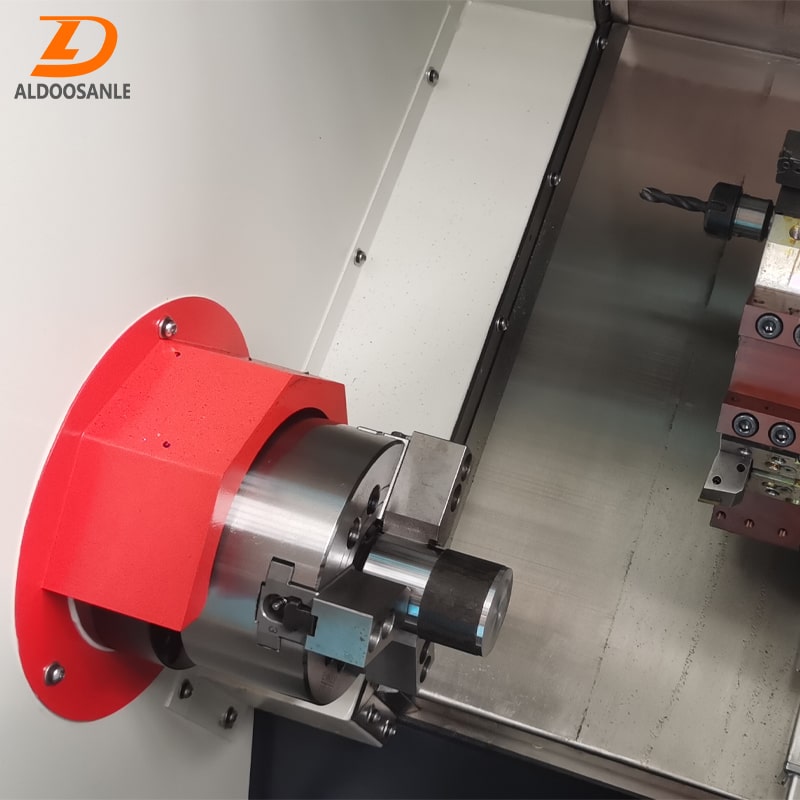

Slant bed cnc lathe machine has high production efficiency and high machining accuracy, and is a relatively advanced industrial lathe.

CNC slant bed lathe machine is a mechanical equipment for processing metal workpieces, and various tools are used to process workpieces.

Product Features

1.Taiwan linear guide with higher precision for mini cnc lathe machine

2.Mini cnc lathe high-speed spindle unit, optional domestic spindle

3.CNC mini metal lathe high rigidity cast iron

4.Lathe machine mini cnc integrated automatic lubrication

5.CNC mini metal lathe machine integrated casting inclined bed CNC lathe

6. The production and processing of CNC lathe turning machine is suitable for new product development and batch modification, and can solve the model specifications such as various types of parts and complex shapes.

7.CNC horizontal lathe has stable production and processing quality and high repeatability.

8.Automatic cnc lathe production and processing uses high-performance numerical control devices to ensure the quality of production and processing.

How to choose a tool for cnc lathe machine slant bed?

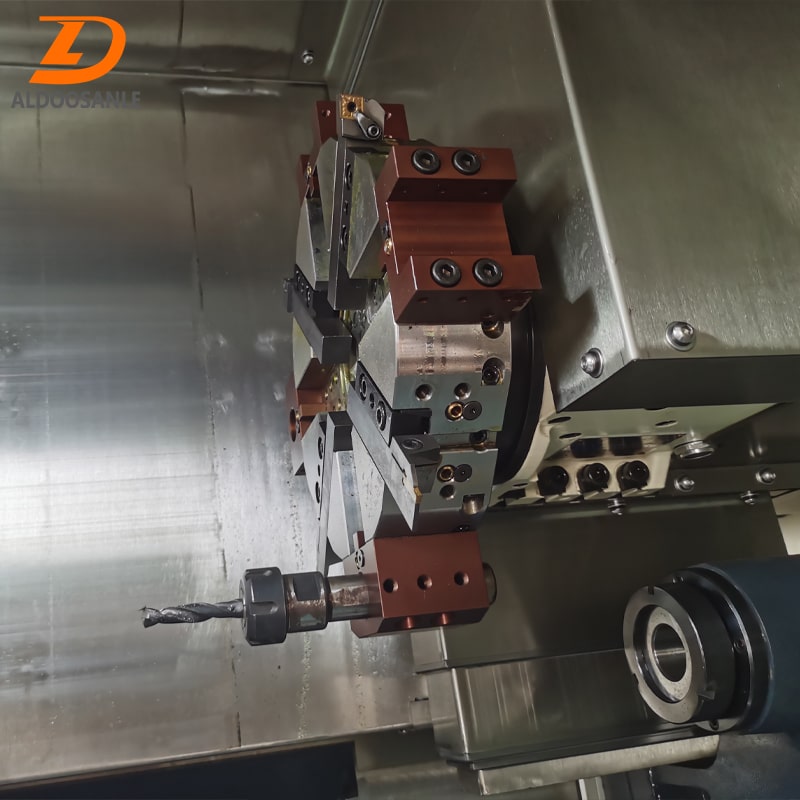

1. The metal cnc lathe machine can be used for both roughing and finishing.

When roughing, it is necessary to select a tool with higher strength and better durability, because roughing is performed with a larger depth of cut and a larger feed rate to process the workpiece.

When finishing, in order to ensure the accuracy of machining, it is necessary to select tools with higher precision and better durability.

2. In order to meet the processing requirements of metal slant bed cnc lathe machine, it is necessary to select according to the type, size and precision level of the tool.

If you want to reduce the time of tool change and facilitate tool setting, you can choose a mechanically clamped tool, which can continue to be used only by changing the blade, and the tool holder can be used repeatedly.

3. During high precision cnc lathe processing, in order to ensure that the tool will not be accidentally damaged and affect the smooth progress of the processing, it is necessary to select a tool with strong adaptability and high reliability and its matching accessories.

cnc lathe manufacture is different from ordinary lathes, ordinary lathes can handle chip breaking and chip removal manually, but cnc lathe machine cannot.

Chips are easy to entangle the tool and the workpiece, which will damage the tool and scratch the processed workpiece, and even affect personal safety and equipment accidents.

Therefore, cnc lathe needs to choose a tool with good chip breaking and chip evacuation performance.

Video

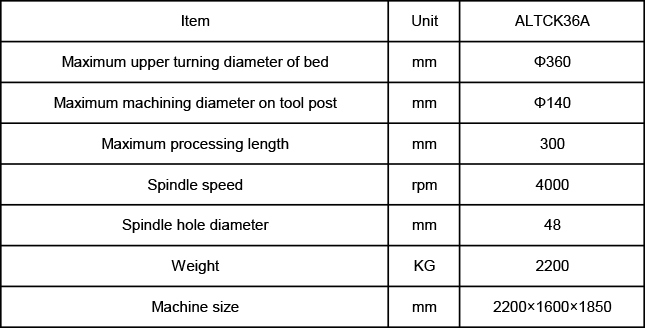

Product Parameters