PRODUCT

ALCK6140×750 cnc lathe machine

ALCK6140×750 cnc lathe machine is an automatic machine tool equipped with a program control system. It can logically process the program specified by the control code or other symbolic instructions, decode it, express it in coded numbers, and input it into the numerical control device through the information carrier. After calculation and processing, various control signals are sent by the numerical control device to control the movement of the machine tool, and the parts are automatically processed according to the shape and size required by the drawing.

ALCK6140×750 cnc lathe machine can turn internal and external circular surfaces, conical surfaces, spherical surfaces, arc surfaces, end faces, grooving, drilling and reaming, special-shaped rotary bodies, metric and inch threads with or without undercuts, and any quadratic curve. Turning end face and reaming, turning various commonly used metric and imperial threads, etc. Materials such as steel, cast iron and non-ferrous metals can be processed.

ALCK6140×750 horizontal cnc lathe features:

1. ALCK6140×750 flat bed cnc lathe has high precision, and the main shaft is supported by high-precision double ball bearings, with low noise, high precision and good stability.

2. The guide rail of ALCK6140×750 flat bed cnc lathe bed is finely ground after super-audio frequency quenching, with high hardness and good rigidity.

3. The electric four-station tool holder is positioned by a precision toothed disc, and the repeat positioning accuracy is high.

4. The tailstock has a fast cam clamping device, which has high working efficiency. There is a device inside the tailstock sleeve to prevent the rotation of the drill bit, which avoids damage to the taper of the inner hole of the tailstock sleeve due to the rotation of the drill bit caused by misoperation, and effectively protects the tailstock components.

5. ALCK6140×750 flat bed cnc lathe system adopts well-known brands at home and abroad, and can be driven by hybrid stepper motor or AC servo motor.

6. Easy to operate, especially suitable for processing complex parts or high-precision mass parts, and is also the first choice for NC teaching.

ALCK6140×750 horizontal cnc lathe use:

1. Tooling field: ALCK6140×750 cnc metal lathe processing is not only an excellent direct manufacturing process, but also an indirect manufacturing process, which can assist injection molding and other processes. It facilitates machining of various steels and strong aluminum. Machined parts such as metal molds can be filled with other materials to create a large number of products.

2. Aerospace industry: The aerospace industry has a long history with CNC machining. Metal aircraft components are machined with the highest precision. This is very important for safety-critical applications. Additionally, the CNC-compatible range of engineered metals provides aerospace engineers with plenty of options.

3. Weapon manufacturing field: ALCK6140×750 cnc metal lathe is developed and designed for multi-station processing of complex parts, mainly used for grinding inner holes and end faces of discs, shafts (or similar parts), suitable for mass production of parts, and has unique advantages of high precision and high efficiency.

4. Shipbuilding and nautical field: ALCK6140×750 cnc metal lathe is widely used in the manufacture of large crankshafts in ships, marine machinery and instrument manufacturing, etc. The high-precision requirements of the shipbuilding industry for parts make CNC lathes an essential processing equipment. CNC machines can continuously produce complex, multi-dimensional metal and plastic parts of various shapes and sizes. It provides efficient, convenient and precise production capacity.

ALCK6140×750 horizontal cnc lathe configuration:

1. Ordinary main motor

2. Domestic frequency converter

3. Three-jaw chuck

4. Tailstock

5. Four-station electric knife holder

6. Automatic lubrication system

7. Electric cooling system

8. Lighting system

9. Semi-enclosed shield

10. Electrical control components

11. A full set of technical information

12. Random standard accessories and tools

ALCK6140×750 automatic cnc lathe optional configuration:

1. Overall bed

2. Integral bed foot

3. Eight-station electric knife holder

4. Hydraulic Chuck

5. Electric chuck

6. Hydraulic tailstock

7. Center bracket

8. Frequency conversion motor

9. Servo motor

10. Electric gate

video:

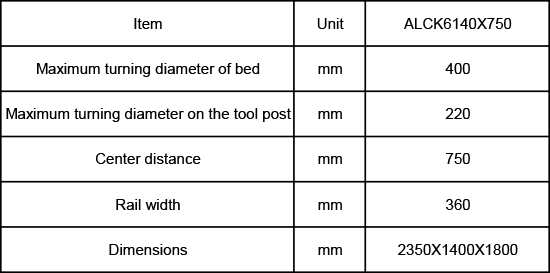

Product parameters: