PRODUCT

ALCK6163X1500 cnc lathe machine

6163×1500 cnc lathe machine is an electromechanical integrated processing machine tool, which is suitable for processing short shaft and disk mechanical parts. One programming input can automatically realize the machining of outer circle, inner hole, thread and complex arc surface of mechanical parts. Widely used in mechanical processing of parts in machinery, automobiles, motorcycles, oil pump nozzles, chemicals, instruments, medical and other industries.

ALCK6163×1500 cnc lathe machineis a fully automatic lathe with high precision and high efficiency. The lathe can be equipped with multiple station turrets or power turrets. It can perform high-precision machining of complex processes such as straight lines, arcs, metric and inch threads, multi-start threads, polygons, multi-faces, and multi-angles, and has played a good economic effect in the mass production of complex parts.

ALCK6163×1500 flat bed cnc lathe features:

1. The machine tool has high precision, and the main shaft is supported by double ball bearings, with low noise, high precision and good stability.

2. It can turn various rotating surfaces, such as cylindrical surfaces, round surfaces, special-shaped surfaces, etc., and can perform grooving, threading, boring, reaming,

3. The guide rail of the bed is finely ground after audio frequency quenching, with high hardness and good rigidity.

4. The ball screw adopts the overall internal circulation screw, supported and pre-tightened by paired angular contact ball bearings. Guide rails, screw rods, etc. adopt centralized automatic lubrication, which has the characteristics of flexible movement, reduced thermal deformation, and stable precision.

5. The electric four-station tool holder is positioned by a gear plate, and the repeat positioning accuracy is high.

6. The tailstock has a cam tightening device, and there is a device for rotating the drill bit in the tailstock sleeve, which avoids damage to the tailstock sleeve due to the rotation of the drill bit caused by misoperation, and protects the tailstock components.

ALCK6163×1500 horizontal cnc lathe use:

1. Railway locomotive manufacturing industry: ALCK6163×1500 automatic cnc lathe is aimed at high-speed rail locomotive body, axle, wheel and other parts.

2. Mold processing and manufacturing industry: The precision of parts is required to be high, and the surface precision mainly refers to the surface roughness. Cylindrical parts with high requirements for cylindricity; conical parts with high requirements for plain straightness, roundness and inclination; rotary parts with special threads. ALCK6163×1500 automatic cnc lathe can better solve this problem.

3. Defense industry: The ability of ALCK6163×1500 automatic cnc lathe to provide replacement parts and upgrade components on demand is especially useful in this industry. Therefore, it is suitable for components that require continuous innovation and safety.

4. Medical business field: ALCK6163×1500 flat bed cnc lathe can be used in various medical safety materials. Since the process is suitable for one-off custom parts, it has many applications in the medical industry. The tight tolerances offered by ALCK6163×1500 flat bed cnc lathe machining are essential for high performance machining of medical components.

ALCK6163×1500 turning cnc lathe standard configuration:

1. CNC system

2. Four-station electric knife holder

3. Ordinary three-jaw chuck

4. Ordinary tailstock

5. Frequency conversion main motor

6. Cooling system, automatic lubrication

ALCK6163×1500 turning cnc lathe optional configuration:

1. Same server main motor

2. Pneumatic or hydraulic chuck

3. Pneumatic hydraulic collet

4. Six or eight station tool post

video:

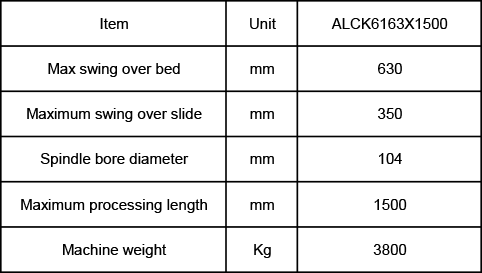

Product parameters: