PRODUCT

ALCK6163X1500 cnc lathe machine has the characteristics of high precision, high efficiency and multi-function, and is suitable for the parts processing needs of automobile manufacturing, aerospace, machinery manufacturing, optoelectronic industry, petrochemical industry and other industries. CNC lathe machine can realize a variety of processing techniques, improve production efficiency and product quality.

Features of horizontal CNC lathe:

1. Advanced numerical control system: ALCK6163X1500 horizontal CNC lathe adopts advanced numerical control system, which has the characteristics of high performance and high precision, supports various turning, threading and other functions, is easy to operate, and improves production efficiency and machining accuracy.

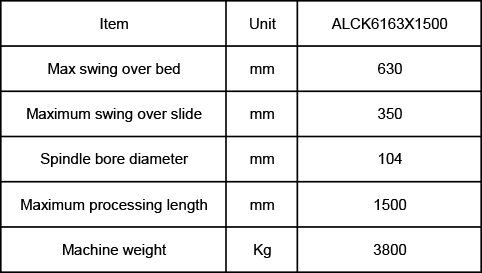

2. High-precision machining: The horizontal CNC lathe is equipped with a high-precision spindle and a servo drive system, which can realize high-precision turning and ensure the dimensional accuracy and surface quality of the parts.

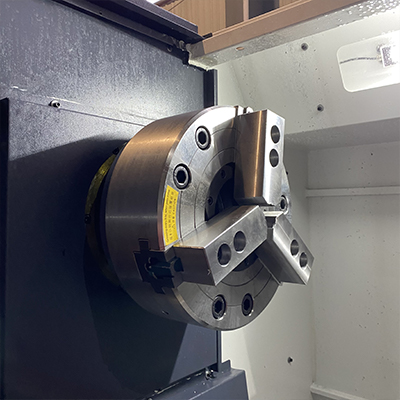

3. Multifunctional processing: ALCK6163X1500 horizontal CNC lathe has various processing functions, including turning, boring, tapping, stretching, drilling, etc., which is suitable for the processing requirements of complex parts.

4. Good stability: The horizontal CNC lathe adopts a stable machine tool structure and a high-rigidity guide rail design, which ensures the stability and precision during processing.

5. High degree of automation: ALCK6163X1500 horizontal CNC lathe is equipped with automatic tool change system, automatic tool length measurement system and other automatic equipment, which can realize automatic production and improve production efficiency.

ALCK6163X1500 flat bed cnc lathe is widely used in the following industries:

1. Automobile manufacturing industry: used for the processing of auto parts, such as engine parts, transmission system parts, etc.

2. Aerospace industry: used for the processing of aerospace parts, such as aircraft engine parts, aerospace structural parts, etc.

3. Machinery manufacturing industry: used for processing various mechanical parts, such as shafts, gears, flanges, etc.

4. Optoelectronics industry: used for processing optical devices, precision instruments and meters, etc.

5. Petrochemical industry: used to process parts of petrochemical equipment, such as valves and pipe fittings.

Processing technology:

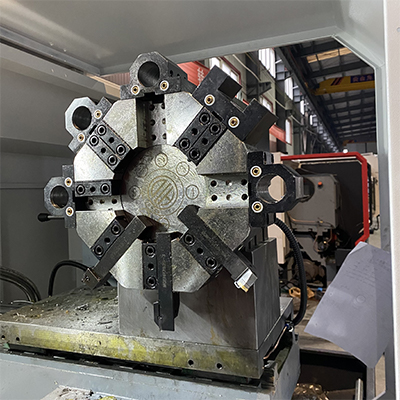

1. Outer circle turning: CNC metal lathe rotates the workpiece on the spindle by controlling the numerical control system, and moves the tool on the workpiece to realize the turning process of the outer circle of the workpiece. Outer contours of different shapes can be realized, such as cylindrical surface, conical surface, spherical surface, etc.

2. Inner hole processing: ALCK6163X1500 cnc metal lathe can rotate and move the tool inside the workpiece to realize the machining of the inner hole of the workpiece, including drilling, reaming, boring, etc.

3. Thread processing: cnc metal lathe can control the feed of the tool and the rotation speed of the spindle through the numerical control system to realize the thread processing of the workpiece, including internal and external threads.

4. Boring processing: ALCK6163X1500 cnc metal lathe can realize precision machining of workpiece holes through boring tools, including machining of precision holes and machining of precision matching holes.

5. Tapping processing: cnc metal lathe can be used for tapping processing through tools, including tapping of internal and external threads, and is used for processing threaded parts.

Video

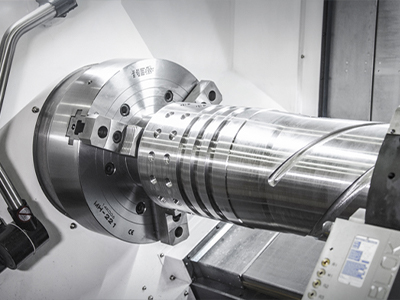

Product Parameters