PRODUCT

CNC lathe turning can produce flats and threads, as well as very complex three-dimensional products; can be used with extreme precision for both small and large parts.

Mini cnc lathe machine is usually used to execute/produce precision circles with outer diameter (OD) and inner diameter (ID). According to the needs of different industries, cnc lathe fanuc can process almost any kind of structure.

Product Features

1. The design of CNC lathe is very spacious, with larger tool working space and improved chip removal ability.

2.Metal cnc lathe wide support saddle with maximum rail length will significantly improve stability and reduce vibration.

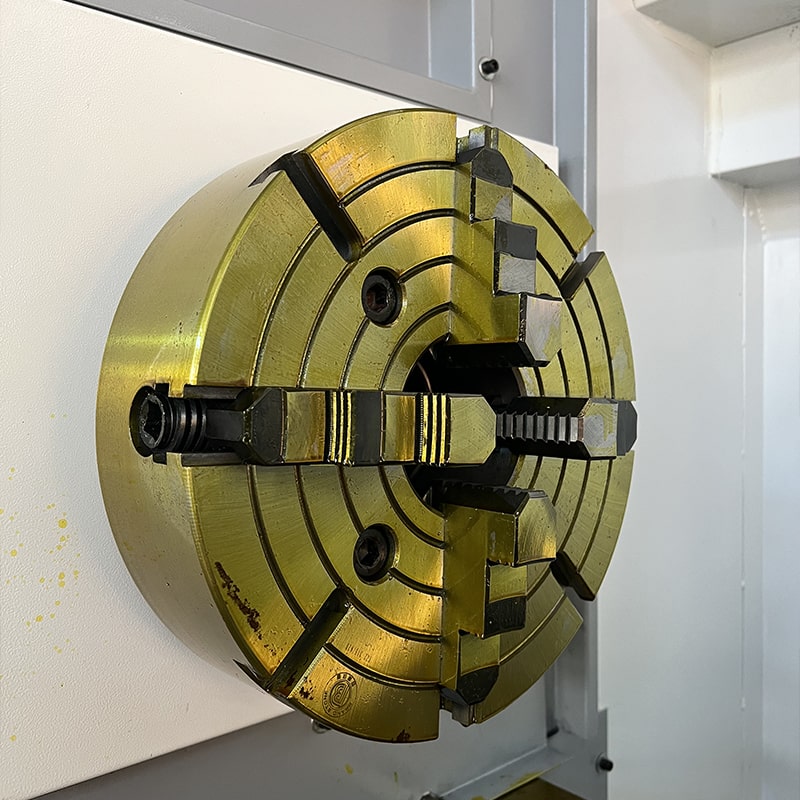

3. The CNC lathe machine adopts an innovative large spindle head design, which can achieve excellent rigidity and minimal influence of operating temperature fluctuations.

4. Rigid tailstock for shaft machining provides additional flexibility for production operations.

Application industries of Horizontal cnc lathe:

Heavy duty cnc lathe machines are commonly used in oil and gas, automotive, aerospace, medical, electronics, mining, power plants, steel and paper mills, and shipbuilding industries, just to name a few.

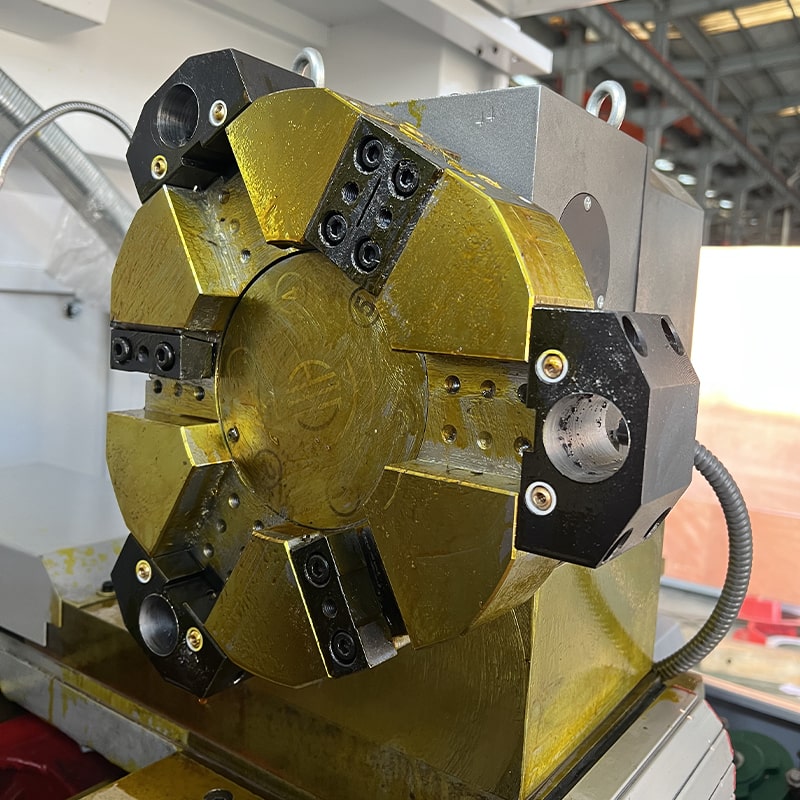

High precision cnc lathe is often equipped with live tooling that can work in multiple axes.

For example, they might include X and Y axes, combine a second turret with a different tool, or include a sub/secondary spindle. These features help to perform different milling, drilling and tapping operations more efficiently and flexibly.

Video

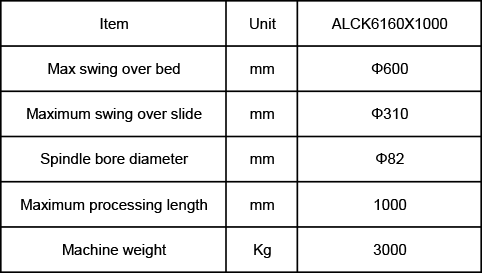

Product Parameters