PRODUCT

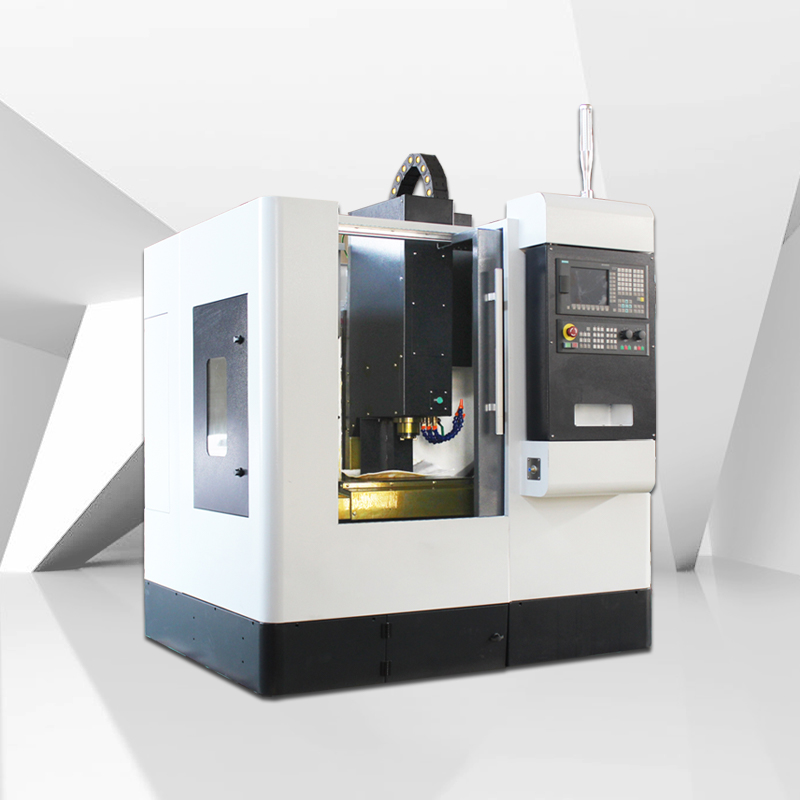

Vertical Machining Center ALVMC300

Vertical Machining Center (VMC) is a high-precision CNC machine tool with many unique features and wide applications. This article will introduce the main features of the VMC300 model and its application in different application industries.

The VMC300 is a multifunctional vertical machining center with high precision, high rigidity and a wide range of applications. It plays an important role in industries such as aerospace, automobile manufacturing, medical equipment, electronic manufacturing, and mold manufacturing, helping manufacturers improve production efficiency and product quality.

Main features of VMC300 CNC milling machine:

1. Vertical structure: The VMC300 CNC milling machine adopts a vertical structure. The workpiece is clamped on the workbench, and the tool enters from above through the spindle. This structure helps to improve the stability of the workbench and work efficiency.

2. High precision: VMC300 CNC milling machine has high-precision processing capabilities and can be used to process complex parts and high-precision work. Its accuracy is usually at the micron level and can meet many precision machining requirements.

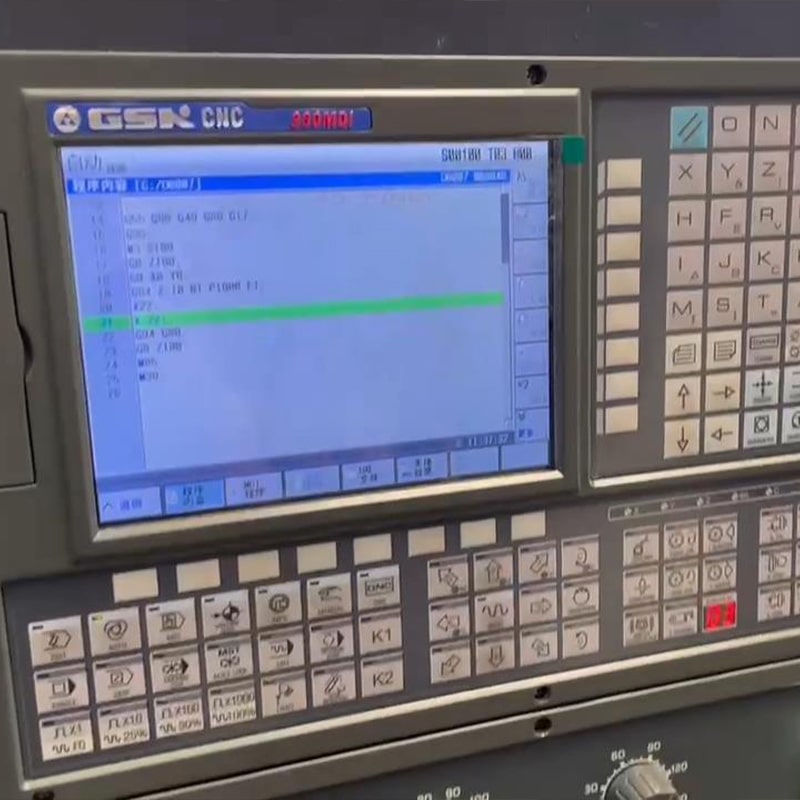

3. Multi-axis control: VMC300 CNC milling machines are usually equipped with a multi-axis control system, which can control multiple motion axes at the same time to achieve complex processing operations, such as cutting, milling, drilling, etc.

4. Automation: VMC300 vertical machining center can be integrated with automation equipment, such as automatic tool changing system and automatic workpiece loading and unloading system, thereby improving production efficiency and reducing labor costs.

5. Rigid structure: VMC300 vertical machining center usually adopts a solid machine tool structure, which has excellent rigidity and stability and is suitable for high load and high-speed processing.

6. User-friendly: The VMC300 vertical machining center is equipped with an intuitive human-machine interface that is easy to operate and program, allowing operators to easily master its functions.

Application industries of VMC300 small CNC milling machine:

1. Aerospace: VMC300 small CNC milling machine is widely used in the aerospace industry for processing aircraft parts, engine parts and other key components. Its high precision and rigidity make it ideal for manufacturing aerospace components.

2. Automobile manufacturing: The automobile manufacturing industry is also one of the main application areas of the VMC300 small CNC milling machine. It is used to process automobile engines, chassis components, brake systems and other critical parts to ensure the quality and performance of the car.

3. Medical equipment: Medical equipment manufacturing requires high-precision parts. The VMC300 small CNC milling machine can be used to process parts of medical equipment such as prostheses, surgical tools and medical instruments to ensure their accuracy and reliability.

4. Electronics manufacturing: In the electronics manufacturing industry, the VMC300 small vertical machining center is used to manufacture electronic components, printed circuit boards and other parts for electronic equipment. Its high-precision and high-speed processing capabilities meet the needs of the electronics industry for small, precision parts.

5. Mold manufacturing: VMC300 small vertical machining center is also widely used to manufacture molds and mold parts. Its high precision and multi-axis control can process complex molds and meet the mold needs of various industries.

Video

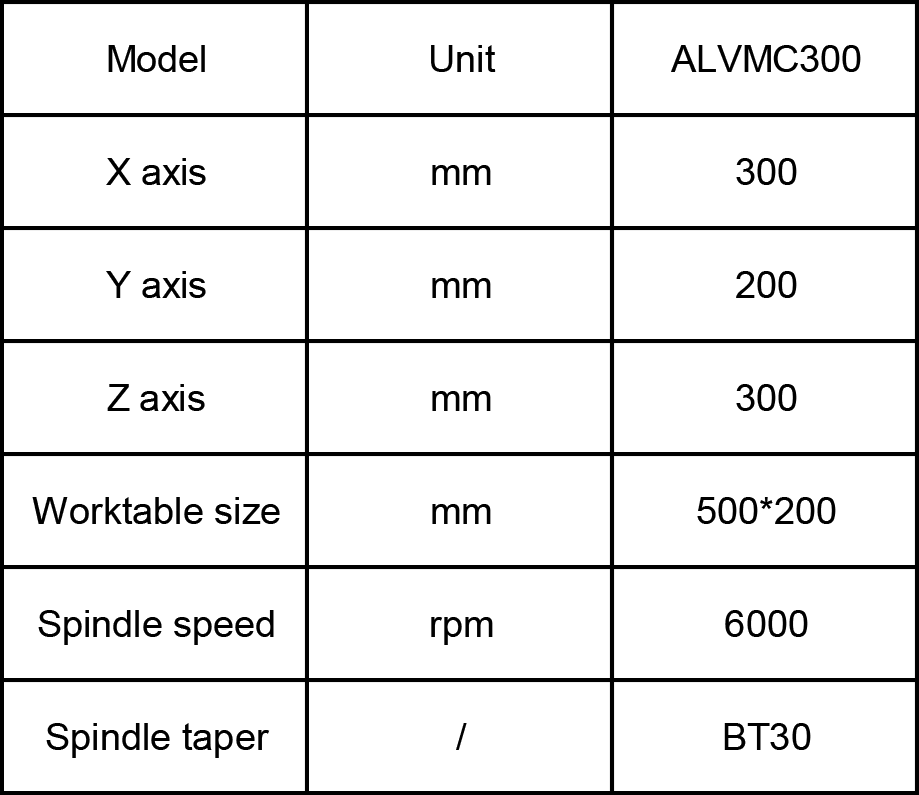

Technical Parameters