PRODUCT

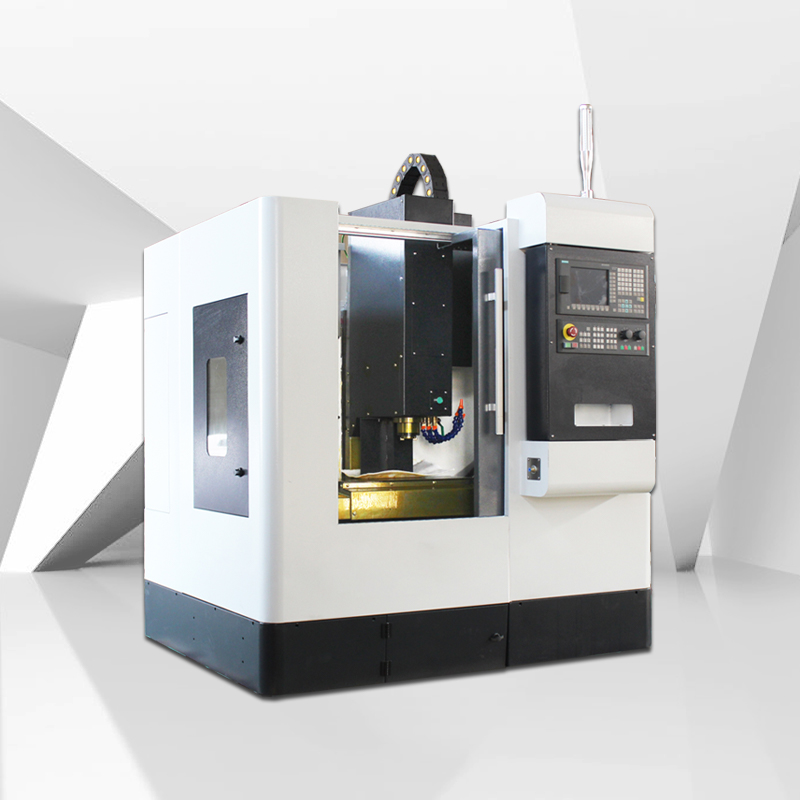

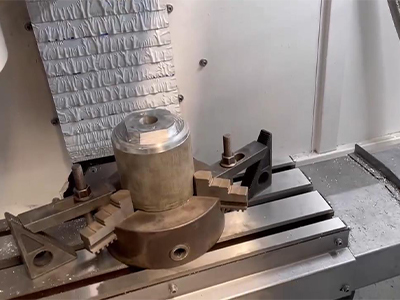

Vertical machining center is a kind of high-efficiency and high-precision processing equipment, which is widely used in manufacturing industry. ALVMC300 is a high-quality vertical machining center. Its features include high precision, high efficiency, and simple operation, making it widely used in various processing fields.

ALVMC300 CNC vertical machining center is a kind of CNC machining equipment. CNC vertical machining center has the advantages of multi-function, high precision, high efficiency, and simple operation. Therefore, CNC metal milling machine is widely used in various processing fields.

The following are some characteristics and application industries of CNC vertical machining center:

1. High precision: ALVMC300 CNC vertical machining center adopts precise processing technology and high-precision sensors, which can realize high-precision processing tasks, such as precision machining of parts, manufacturing of molds, etc.

2. High efficiency: CNC vertical machining center has the functions of high-speed cutting and fast feed, which greatly improves the processing efficiency and production efficiency, and is suitable for large-scale production processing fields, such as automobile manufacturing, machine tool manufacturing, mold manufacturing, etc.

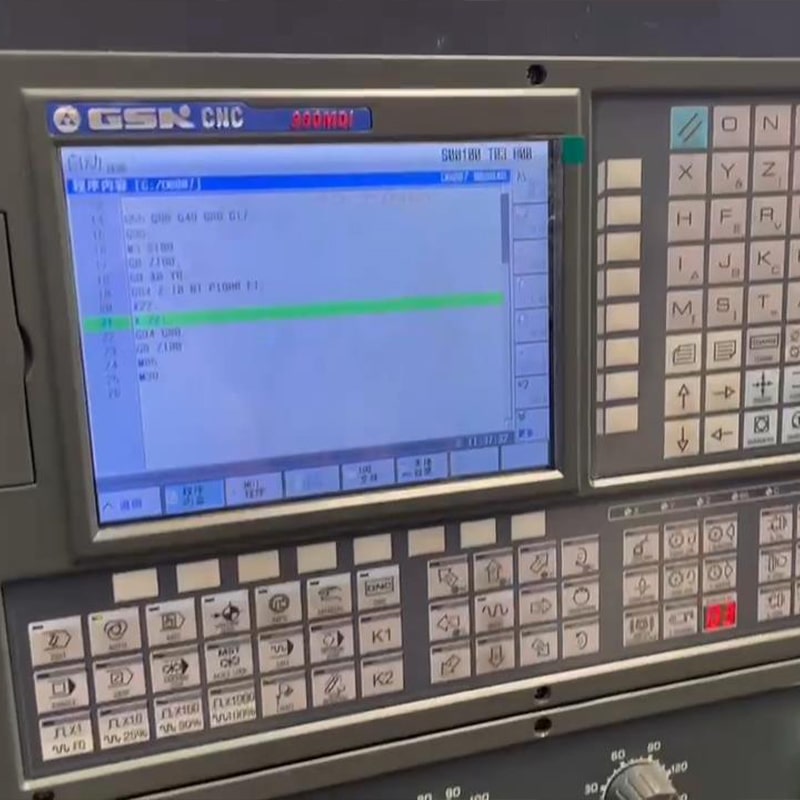

3. Simple operation: ALVMC300 CNC vertical machining center is equipped with a user-friendly operation interface, which enables operators to get started quickly and improves production efficiency and work efficiency.

ALVMC300 vertical machining center has a wide range of applications in the following industries:

1. Automobile manufacturing: vertical machining centers are widely used in automobile manufacturing, such as engine block, wheel hub, steering gear housing, etc.

2. Machine tool manufacturing: the vertical machining center can quickly and efficiently process various machine tool parts, such as spindle box, bed, slide plate, etc.

3. Mold manufacturing: vertical machining centers are also widely used in the field of mold manufacturing, such as injection molds, die-casting molds, drawing molds, etc.

Video

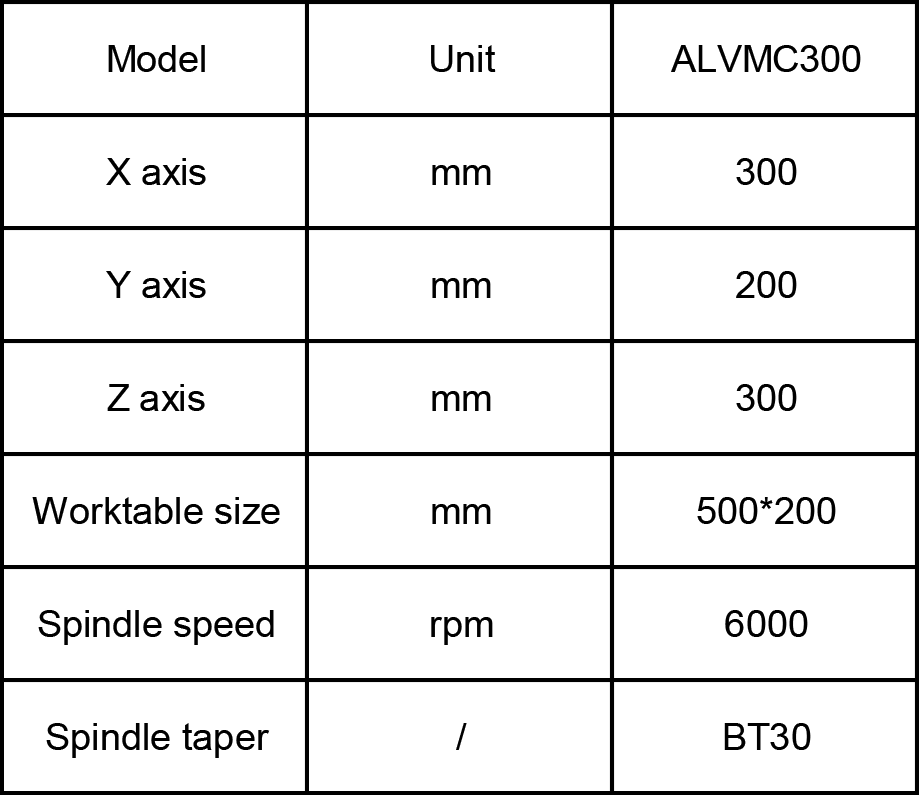

Technical Parameters